flexej Expansion bellows

24hr Shipping

On all stock items ordered.

Mon-Thur by 2pm, 10am Fridays

Design & Manufacturing

Full in-house design & manufacture to EN / ASME / PED.

ISO14001 Accreditation

FlexEJ has an accredited Environmental Management System.

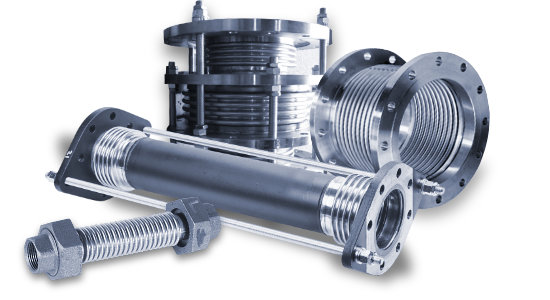

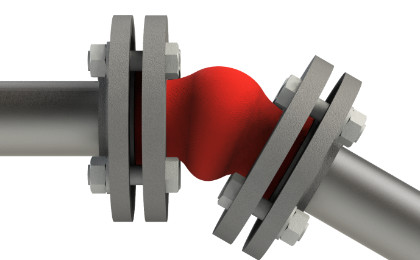

Expansion Bellows

FlexEJ is a UK expansion bellows / pipe expansion joint manufacturer. Our highly qualified and experienced team design build all types of expansion bellows – stock pipe expansion joints – customised bellows assemblies – fully engineered expansion joints in our West Midlands factory. FlexEJ’s extensive UK stock of standard rubber bellows and metal bellows are available for next day delivery across the UK. Whatever your needs, FlexEJ is here to help.

Do see our expansion bellows range overview and our expansion joint finders further down this page and for stock items head to our expansion bellows shop pages.

PRODUCT GUIDES

EXPANSION BELLOWS

WHAT IS A PIPE EXPANSION JOINT?

It’s a flexible element in the piping system that allows the piping to move easily without exerting excessive forces on the system…

Thermal Expansion

Pipes expand and contract in length as they change temperature – these changes can exert huge forces on the system.

Movements

Axial, Lateral and Angular movements are acceptable but Torsional movement must be avoided.

Misalignment

It is quite normal during installation to have some misalignment between piping and equipment.

Stock or engineered

FlexEJ have a wide range of expansion of joints in stock – plus we can design and build to your exact requirements.

Pipe Expansion Bellows Explained

Pipe expansion bellows, otherwise known as pipe expansion joints or pipe compensators are used in piping where the movement in the pipe exceeds the natural flexibility of the piping.

Pipes move for three main reasons, Structural (the pipe traverses something that is moving), Thermal (the contents of the pipe change in temperature causing it to expand or contract) and Misalignment (the end points are not aligned). Structural and Thermal movements tend to be cyclic. Natural flexibility is the piping’s own inherent flexibility, which reduces with increasing diameter – once exceeded will cause failure in the piping system. Pipe expansion bellows increase the flexibility in the piping so reducing loads on the system and connected equipment to safe levels.

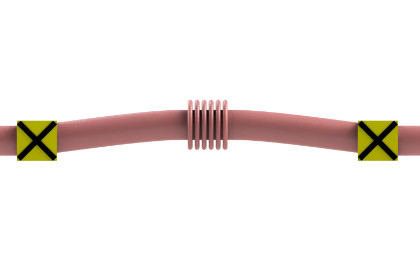

There are three types of movement that expansion bellows are designed to allow Axial, Angular and Lateral. Torsional movement – rotation about the pipe axis – is not allowable. Some movements can happen together – concurrent – some can only occur by themselves – non-concurrent. For metal bellows, the number of cycles of movement is a key design criterion, but this is not a concern for rubber bellows.

How to select a pipe expansion joint

This is a key criteria in deciding between rubber and metal bellows; over 90°C operation metal bellows should be a consideration, over 130°C operation metal bellows become the only viable selection.

This is a key criteria in deciding between rubber and metal bellows; over 90°C operation metal bellows should be a consideration, over 130°C operation metal bellows become the only viable selection. For rubber bellows, it is necessary to choose a rubber compound that is compatible with the fluid and service – we have 10 compounds available.

For metal bellows, stainless steel is the most common material and is compatible with a very wide range of fluids.

For rubber bellows, it is necessary to choose a rubber compound that is compatible with the fluid and service – we have 10 compounds available.

For metal bellows, stainless steel is the most common material and is compatible with a very wide range of fluids. The pressure capability of bellows generally decreases with diameter. Most standard rubber bellows up to DN250 are rated 16 barg and 10 barg to DN1000. Standard metal bellows are typically rated at 10 barg but can be designed for much higher pressures.

The deration of the pressure capability of the bellows with temperature must be considered – metal bellows above 250 °C and for rubber bellows above 50 °C.

The pressure capability of bellows generally decreases with diameter. Most standard rubber bellows up to DN250 are rated 16 barg and 10 barg to DN1000. Standard metal bellows are typically rated at 10 barg but can be designed for much higher pressures.

The deration of the pressure capability of the bellows with temperature must be considered – metal bellows above 250 °C and for rubber bellows above 50 °C. The direction and magnitude of the movements needs to be calculated or observed. Avoid combining non-concurrent movements, as the bellows will be over designed for the real situation.

The direction and magnitude of the movements needs to be calculated or observed. Avoid combining non-concurrent movements, as the bellows will be over designed for the real situation. All bellows exert two forces on the piping system and must be taken into account.

Spring force is the force required to move the bellows mechanically and generally assumed to be directly proportional to the movement. Pressure force is often much greater than the spring force – it is generated by the pressure inside the bellows pushing on the convolution.

All bellows exert two forces on the piping system and must be taken into account.

Spring force is the force required to move the bellows mechanically and generally assumed to be directly proportional to the movement. Pressure force is often much greater than the spring force – it is generated by the pressure inside the bellows pushing on the convolution. Metal bellows have a defined cycle life most often calculated using the EJMA code. The number of cycles the bellows will be subjected to need to be estimated to ensure adequate life is designed into the bellows.

Call our expert team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk if you think we could help – or use Live Chat on this web site – we are here to help.

Metal bellows have a defined cycle life most often calculated using the EJMA code. The number of cycles the bellows will be subjected to need to be estimated to ensure adequate life is designed into the bellows.

Call our expert team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk if you think we could help – or use Live Chat on this web site – we are here to help.What About More Complex, Industrial Expansion Joints?

More complex and larger diameter expansion joints can also be assembled from thousands of stock components, restraints and flanges. Sizes not available from stock can often be either be shipped within 2-3 days or, when necessary, custom designed and engineered from scratch. More on this in the next section. Or call us on 01384 881188. We’re here to help and have qualified experts on-hand.

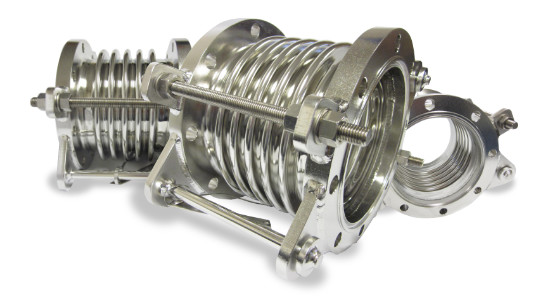

FlexEJ’s Custom-Engineered Expansion Bellows

FlexEJ designs and manufactures metal bellow pipe expansion joints to meet customer’s exact requirements. Our design and application expertise allows us to provide reliable metal bellows for difficult critical services: very hot, corrosive, high pressure, high vacuum – all with documentation to meet any project need. The bellows calculation will be performed using EJMA 10; the expansion joint may be specified to any appropriate code such as B31.3. We do not approach engineered bellows with a standard product tool set, we custom engineer to provide the optimum solution.

Metal Expansion Joint Manufacture

Design & build

METAL EXPANSION JOINT MANUFACTURE

Metal expansion joints from DN25 to DN3000+

Full multi case, concurrent / non concurrent movement design using our own EJMA10 bellows and hardware calculation tools.

Overall design to B31.3 or EN13445 with PED as appropriate supported by SolidWorks, FEA and thermal modelling for high temperature designs requiring internal insulation. We are happy to work to any client specifications and to submit full design and manufacturing documentation for approval.

Bellows materials include 304, 321 316(H), 625, 800(H), 825, expansion joint materials include carbon steels, CrMo, stainless steels. All with liners, covers, tie rods, hinges, gimbals, pressure balanced, insulation, refractory as required to deliver a complete pipe expansion joint to your exact requirements.

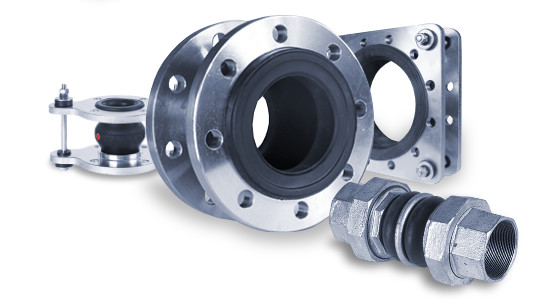

Rubber Expansion Joint Manufacture

Design & Build

RUBBER EXPANSION JOINT MANUFACTURE

Rubber expansion joints from DN25 to DN3600+

FlexEJ’s sister company Safetech designs and manufactures rubber expansion joints. Rubbers available include WRAS approved EPDM, Nitrile and VITON.

Any flange drilling pattern can be accommodated along with tie rods, hinges, gimbals or pressure balanced designs. Backing flanges in carbon steel or stainless steel supplied in segments with integral tie rod lugs or a one piece.

Safetech also manufactures large diameter rubber hoses, rectangular rubber bellows, reducing rubber bellows and are happy to consider any product or design request.

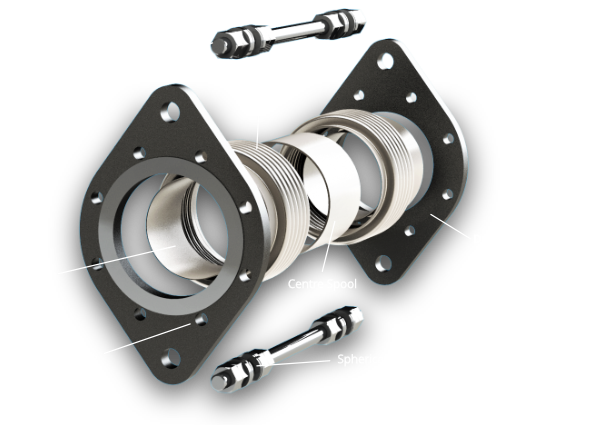

INDUSTRIAL METAL BELLOWS

Configured and stock

FlexEJ’s Industrial range combines stock bellows with a wide range of flanges, pipe ends and hardware to provide a highly specified expansion joint product in a short lead time.

PHARMACEUTICAL EXPANSION JOINT MANUFACTURE

For aseptic and hygienic applications

This is a product which FlexEJ has developed to address a need for a self-draining, high surface finish metal bellow rated typically at 270°C and 10 BarG

PTFE EXPANSION BELLOWS

Configurable expansion joints from DN25 to DN600

FlexEJ’s PTFE bellows feature multilayer solid PTFE convolutions. PTFE is almost totally chemically inert and highly insoluble in most solvents or chemicals. This makes it an excellent choice in highly corrosive environments or where media contamination is an issue.

FlexEJ’s Pre-Manufactured Stock Expansion Bellows

FlexEJ have a wide range of stock bellows, both metal and rubber and cover the majority of common requirements. All our stock is available in our web shop for next day delivery. Our stock products are manufactured to very high standards and include the Elaflex range of premium quality rubber bellows.

ELAFLEX RUBBER EXPANSION JOINTS

Renowned for their high quality and durability

Elaflex rubber expansion bellows are available in over 8,000 configuration options of rubber, flange drilling, restraints and PTFE lining. The core range is in stock at FlexEJ backed by a vast and comprehensive stock in Hamburg. Elaflex bellows offer high quality stock based solutions for a huge range of applications.

HVAC METAL BELLOWS

For HVAC and building services applications

FlexEJ’s HVAC range of metal expansion joints are available in diameters from 12mm to 150mm with flanged, copper or union ends to suit the piping being installed. Available from stock or on short lead times

HVAC RUBBER BELLOWS

Available in a wide range of sizes, flange and restraint options

FlexEJ’s HVAC rubber bellows range is intended to offer great value for money for lower temperature and non critical HVAC services. Our standard flanged rubber bellow is EPDM rubber with galvanised mild steel PN16 flanges, tied or untied – a BSP Union-end bellows is also available.

Pipe Expansion Joint Finders and Calculators

We have a couple of easy to use tools and calculators to help you select from BSP, copper-ends or flanged pipe expansion bellows from stock. Our Thermal Expansion Calculator for Piping helps you estimate the increase in length of a pipe run with temperature – most common materials are covered.

Our Advanced Bellows Finder is a quick way to navigate our stock range of bellows, both metal and rubber. With just a few choices you can arrive at the appropriate selection – criteria include pipe size, type, media compatibility, installation length, pressure rating, pipe connection type, conformance and movement axial, lateral and angular. All the products are in the online store with 24hr shipping as standard. If you’re not sure what flange you need our handy Flange Finder should also be useful.

Stock Expansion Joint Finder

Do search for expansion bellows by pipe size, intended media and/or connection hardware to see FlexEJ’s stock bellows options below but don’t hesitate to call us on 01384 881188 or email us for more bespoke or OEM options or if you need any advice at all.

Thermal Expansion in Piping Systems

Thermal expansion and contraction in piping causes significant changes in length of the pipe. This axial movement must be catered for either by natural flexibility or expansion joints in the system – the forces imposed by the thermal movement are considerable and could cause failure.

Please use our Thermal Expansion Calculator for Piping to estimate linear pipe movements for a variety of common pipe materials. Our Advanced Bellows Finder (or shop pages) will help you then find an appropriate bellows by pipe size, material, installation length, permitted movements or operating temperature.

As ever, if you think FlexEJ could help source a one-off or even a range of custom-designed solutions for you then please don’t hesitate to call us.

Can't see what you want? Need help?

Call us. Or use Live Chat.

For instant advice. We can custom-design and engineer almost any expansion joint you need for delivery in the UK or worldwide. Call our expert team on +44 (0) 1384 881188 Or email us sales@flexej.co.uk

Frequently Asked Questions

A. A tie rod is a simple pressure thrust restraint. It will allow reasonable lateral movement but not axial extension; it can allow axial compression if the pressure thrust is overcome by the piping movement. See the movements and pressure thrust FAQs for definitions. For technical assistance please contact us or use our Live Chat facility.

A. All expansion joints exert a force, pushing the pipe ends apart – pressure thrust – which is proportional to the operating pressure and diameter of the bellows. If the expansion joint is unrestrained the piping system must withstand the force, or, alternatively, the expansion joint may have restraints built in to constrain the pressure thrust force. For instance types, tie rod, hinge or gimbal. For technical assistance please contact us or use our Live Chat facility.

A. To design or select a rubber bellows or metal expansion joint we need to know: nominal bore, end type, service, temperature, pressure and required movements. You may also specify in addition your requirements for external hardware – tie rods, hinges, gimbals – internal liner, external cover and instrumentation. Material selections should also be specified to suit the service and associated system piping. For technical assistance please contact us or use our Live Chat facility.

A. The EJMA is the Expansion Joints Manufacturers Association. Their bellows calculation method is most frequently used for metal bellows expansion joint design. EJMA does not cover rubber bellows or metal hose design. For technical assistance please contact us or use the LIVE CHAT link on this page.

Please visit our full FAQ page to see all our frequently asked questions.