PTFE BELLOWS for ULTIMATE CORROSION RESISTANCE

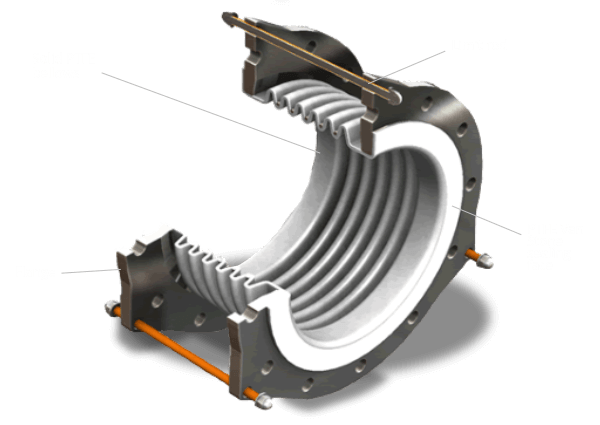

Convoluted multi layer PTFE bellows

24hr Shipping

On all stock items ordered.

Mon-Thur by 2pm, 10am Fridays

Design & Manufacturing

Full in-house design & manufacture to EN / ASME / PED.

ISO14001 Accreditation

FlexEJ has an accredited Environmental Management System.

PTFE Expansion Bellows

PTFE expansion bellows, otherwise known as PTFE expansion joints, offer excellent media compatibility and corrosion resistance.

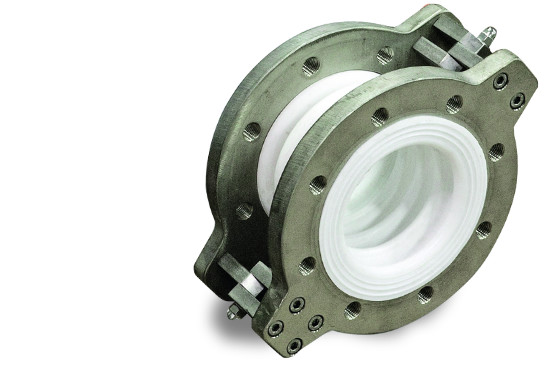

Offered in two ranges – standard ‘R’ and heavy duty ‘RHD’ – with diameters from 25mm to 600mm. All bellows have Van Stone flanges – any drilling available – and limit rods:

PRODUCT GUIDES

PTFE BELLOWS

WHAT IS A CONVOLUTED PTFE EXPANSION BELLOW?

FOR EXCELLENT CORROSION RESISTANCE AND MEDIA COMPATIBILITY..

Materials

Solid, multi-laminated PTFE bellows with coated carbon steel flanges.

Application

Highly corrosive and contamination sensitive media.

Rating

Varies with number of convolutions and strongly with temperature. Electrically conductive.

Design

Minimum porosity and homogeneous wall thickness.

FlexEJ offer two ranges of PTFE bellows:

PTFE BELLOWS – STANDARD DUTY:

| SIZE | LENGTH | PRESSURE RATING | MOVEMENT | IN SHOP |

|---|---|---|---|---|

| DN25-1″ | 42 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 9 mm, Lateral +/- 6 mm, Angular +/- 13 º | |

| DN25-1″ | 54 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 13.5 mm, Lateral +/- 9 mm, Angular +/- 19.5 º | |

| DN25-1″ | 67 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 18 mm, Lateral +/- 12 mm, Angular +/- 26 º | |

| DN25-1″ | 79 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 22.5 mm, Lateral +/- 15 mm, Angular +/- 32.5 º | |

| DN25-1″ | 91 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 27 mm, Lateral +/- 18 mm, Angular +/- 39 º | |

| DN25-1″ | 104 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 31.5 mm, Lateral +/- 21 mm, Angular +/- 45.5 º | |

| DN25-1″ | 116 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 36 mm, Lateral +/- 24 mm, Angular +/- 52 º | |

| DN25-1″ | 128 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 40.5 mm, Lateral +/- 27 mm, Angular +/- 58.5 º | |

| DN25-1″ | 140 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 45 mm, Lateral +/- 30 mm, Angular +/- 65 º | |

| DN32-1¼” | 51 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 9 mm, Lateral +/- 6 mm, Angular +/- 12 º | |

| DN32-1¼” | 66 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 13.5 mm, Lateral +/- 9 mm, Angular +/- 18 º | |

| DN32-1¼” | 81 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 18 mm, Lateral +/- 12 mm, Angular +/- 24 º | |

| DN32-1¼” | 96 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 22.5 mm, Lateral +/- 15 mm, Angular +/- 30 º | |

| DN32-1¼” | 112 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 27 mm, Lateral +/- 18 mm, Angular +/- 36 º | |

| DN32-1¼” | 127 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 31.5 mm, Lateral +/- 21 mm, Angular +/- 42 º | |

| DN32-1¼” | 142 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 36 mm, Lateral +/- 24 mm, Angular +/- 48 º | |

| DN32-1¼” | 157 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 40.5 mm, Lateral +/- 27 mm, Angular +/- 54 º | |

| DN32-1¼” | 172 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 45 mm, Lateral +/- 30 mm, Angular +/- 60 º | |

| DN40-1½” | 52 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 10 mm, Lateral +/- 7 mm, Angular +/- 12 º | |

| DN40-1½” | 68 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 15 mm, Lateral +/- 10.5 mm, Angular +/- 18 º | |

| DN40-1½” | 84 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 20 mm, Lateral +/- 14 mm, Angular +/- 24 º | |

| DN40-1½” | 100 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 25 mm, Lateral +/- 17.5 mm, Angular +/- 30 º | |

| DN40-1½” | 117 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 30 mm, Lateral +/- 21 mm, Angular +/- 36 º | |

| DN40-1½” | 133 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 35 mm, Lateral +/- 24.5 mm, Angular +/- 42 º | |

| DN40-1½” | 149 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 40 mm, Lateral +/- 28 mm, Angular +/- 48 º | |

| DN40-1½” | 165 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 45 mm, Lateral +/- 31.5 mm, Angular +/- 54 º | |

| DN40-1½” | 181 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 50 mm, Lateral +/- 35 mm, Angular +/- 60 º | |

| DN50-2″ | 52 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 10 mm, Lateral +/- 7 mm, Angular +/- 11 º | |

| DN50-2″ | 69 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 15 mm, Lateral +/- 10.5 mm, Angular +/- 16.5 º | |

| DN50-2″ | 85 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 20 mm, Lateral +/- 14 mm, Angular +/- 22 º | |

| DN50-2″ | 101 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 25 mm, Lateral +/- 17.5 mm, Angular +/- 27.5 º | |

| DN50-2″ | 117 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 30 mm, Lateral +/- 21 mm, Angular +/- 33 º | |

| DN50-2″ | 133 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 35 mm, Lateral +/- 24.5 mm, Angular +/- 38.5 º | |

| DN50-2″ | 149 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 40 mm, Lateral +/- 28 mm, Angular +/- 44 º | |

| DN50-2″ | 165 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 45 mm, Lateral +/- 31.5 mm, Angular +/- 49.5 º | |

| DN50-2″ | 181 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 50 mm, Lateral +/- 35 mm, Angular +/- 55 º | |

| DN65-2½” | 58 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 11 mm, Lateral +/- 8 mm, Angular +/- 10 º | |

| DN65-2½” | 79 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 16.5 mm, Lateral +/- 12 mm, Angular +/- 15 º | |

| DN65-2½” | 101 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 22 mm, Lateral +/- 16 mm, Angular +/- 20 º | |

| DN65-2½” | 122 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 27.5 mm, Lateral +/- 20 mm, Angular +/- 25 º | |

| DN65-2½” | 143 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 33 mm, Lateral +/- 24 mm, Angular +/- 30 º | |

| DN65-2½” | 165 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 38.5 mm, Lateral +/- 28 mm, Angular +/- 35 º | |

| DN65-2½” | 186 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 44 mm, Lateral +/- 32 mm, Angular +/- 40 º | |

| DN65-2½” | 208 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 49.5 mm, Lateral +/- 36 mm, Angular +/- 45 º | |

| DN65-2½” | 229 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 55 mm, Lateral +/- 40 mm, Angular +/- 50 º | |

| DN80-3″ | 62 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 11 mm, Lateral +/- 8 mm, Angular +/- 10 º | |

| DN80-3″ | 87 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 16.5 mm, Lateral +/- 12 mm, Angular +/- 15 º | |

| DN80-3″ | 112 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 22 mm, Lateral +/- 16 mm, Angular +/- 20 º | |

| DN80-3″ | 137 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 27.5 mm, Lateral +/- 20 mm, Angular +/- 25 º | |

| DN80-3″ | 162 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 33 mm, Lateral +/- 24 mm, Angular +/- 30 º | |

| DN80-3″ | 188 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 38.5 mm, Lateral +/- 28 mm, Angular +/- 35 º | |

| DN80-3″ | 212 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 44 mm, Lateral +/- 32 mm, Angular +/- 40 º | |

| DN80-3″ | 238 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 49.5 mm, Lateral +/- 36 mm, Angular +/- 45 º | |

| DN80-3″ | 263 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 55 mm, Lateral +/- 40 mm, Angular +/- 50 º | |

| DN100-4″ | 64 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 12 mm, Lateral +/- 9 mm, Angular +/- 9 º | |

| DN100-4″ | 90 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 18 mm, Lateral +/- 13.5 mm, Angular +/- 13.5 º | |

| DN100-4″ | 117 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 24 mm, Lateral +/- 18 mm, Angular +/- 18 º | |

| DN100-4″ | 143 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 30 mm, Lateral +/- 22.5 mm, Angular +/- 22.5 º | |

| DN100-4″ | 169 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 36 mm, Lateral +/- 27 mm, Angular +/- 27 º | |

| DN100-4″ | 196 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 42 mm, Lateral +/- 31.5 mm, Angular +/- 31.5 º | |

| DN100-4″ | 221 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 48 mm, Lateral +/- 36 mm, Angular +/- 36 º | |

| DN100-4″ | 248 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 54 mm, Lateral +/- 40.5 mm, Angular +/- 40.5 º | |

| DN100-4″ | 274 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 60 mm, Lateral +/- 45 mm, Angular +/- 45 º | |

| DN125-5″ | 74 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 13 mm, Lateral +/- 9 mm, Angular +/- 8 º | |

| DN125-5″ | 100 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 19.5 mm, Lateral +/- 13.5 mm, Angular +/- 12 º | |

| DN125-5″ | 126 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 26 mm, Lateral +/- 18 mm, Angular +/- 16 º | |

| DN125-5″ | 151 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 32.5 mm, Lateral +/- 22.5 mm, Angular +/- 20 º | |

| DN125-5″ | 177 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 39 mm, Lateral +/- 27 mm, Angular +/- 24 º | |

| DN125-5″ | 204 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 45.5 mm, Lateral +/- 31.5 mm, Angular +/- 28 º | |

| DN125-5″ | 229 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 52 mm, Lateral +/- 36 mm, Angular +/- 32 º | |

| DN125-5″ | 255 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 58.5 mm, Lateral +/- 40.5 mm, Angular +/- 36 º | |

| DN125-5″ | 281 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 65 mm, Lateral +/- 45 mm, Angular +/- 40 º | |

| DN150-6″ | 76 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 14 mm, Lateral +/- 9 mm, Angular +/- 7 º | |

| DN150-6″ | 103 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 21 mm, Lateral +/- 13.5 mm, Angular +/- 10.5 º | |

| DN150-6″ | 130 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 28 mm, Lateral +/- 18 mm, Angular +/- 14 º | |

| DN150-6″ | 155 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 35 mm, Lateral +/- 22.5 mm, Angular +/- 17.5 º | |

| DN150-6″ | 182 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 42 mm, Lateral +/- 27 mm, Angular +/- 21 º | |

| DN150-6″ | 209 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 49 mm, Lateral +/- 31.5 mm, Angular +/- 24.5 º | |

| DN150-6″ | 234 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 56 mm, Lateral +/- 36 mm, Angular +/- 28 º | |

| DN150-6″ | 262 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 63 mm, Lateral +/- 40.5 mm, Angular +/- 31.5 º | |

| DN150-6″ | 289 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 70 mm, Lateral +/- 45 mm, Angular +/- 35 º | |

| DN200-8″ | 77 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 15 mm, Lateral +/- 10 mm, Angular +/- 6 º | |

| DN200-8″ | 105 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 22.5 mm, Lateral +/- 15 mm, Angular +/- 9 º | |

| DN200-8″ | 133 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 30 mm, Lateral +/- 20 mm, Angular +/- 12 º | |

| DN200-8″ | 161 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 37.5 mm, Lateral +/- 25 mm, Angular +/- 15 º | |

| DN200-8″ | 186 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 45 mm, Lateral +/- 30 mm, Angular +/- 18 º | |

| DN200-8″ | 215 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 52.5 mm, Lateral +/- 35 mm, Angular +/- 21 º | |

| DN200-8″ | 243 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 60 mm, Lateral +/- 40 mm, Angular +/- 24 º | |

| DN200-8″ | 268 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 67.5 mm, Lateral +/- 45 mm, Angular +/- 27 º | |

| DN200-8″ | 296 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 75 mm, Lateral +/- 50 mm, Angular +/- 30 º | |

| DN250-10″ | 78 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 16 mm, Lateral +/- 10 mm, Angular +/- 6 º | |

| DN250-10″ | 108 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 24 mm, Lateral +/- 15 mm, Angular +/- 9 º | |

| DN250-10″ | 137 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 32 mm, Lateral +/- 20 mm, Angular +/- 12 º | |

| DN250-10″ | 166 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 40 mm, Lateral +/- 25 mm, Angular +/- 15 º | |

| DN250-10″ | 196 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 48 mm, Lateral +/- 30 mm, Angular +/- 18 º | |

| DN250-10″ | 225 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 56 mm, Lateral +/- 35 mm, Angular +/- 21 º | |

| DN250-10″ | 254 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 64 mm, Lateral +/- 40 mm, Angular +/- 24 º | |

| DN250-10″ | 284 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 72 mm, Lateral +/- 45 mm, Angular +/- 27 º | |

| DN250-10″ | 313 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 80 mm, Lateral +/- 50 mm, Angular +/- 30 º | |

| DN300-12″ | 80 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 16 mm, Lateral +/- 10 mm, Angular +/- 5 º | |

| DN300-12″ | 110 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 24 mm, Lateral +/- 15 mm, Angular +/- 7.5 º | |

| DN300-12″ | 140 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 32 mm, Lateral +/- 20 mm, Angular +/- 10 º | |

| DN300-12″ | 170 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 40 mm, Lateral +/- 25 mm, Angular +/- 12.5 º | |

| DN300-12″ | 200 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 48 mm, Lateral +/- 30 mm, Angular +/- 15 º | |

| DN300-12″ | 230 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 56 mm, Lateral +/- 35 mm, Angular +/- 17.5 º | |

| DN300-12″ | 261 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 64 mm, Lateral +/- 40 mm, Angular +/- 20 º | |

| DN300-12″ | 291 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 72 mm, Lateral +/- 45 mm, Angular +/- 22.5 º | |

| DN300-12″ | 321 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 80 mm, Lateral +/- 50 mm, Angular +/- 25 º | |

| DN350-14″ | 91 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 17 mm, Lateral +/- 10 mm, Angular +/- 5 º | |

| DN350-14″ | 122 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 25.5 mm, Lateral +/- 15 mm, Angular +/- 7.5 º | |

| DN350-14″ | 154 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 34 mm, Lateral +/- 20 mm, Angular +/- 10 º | |

| DN350-14″ | 185 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 42.5 mm, Lateral +/- 25 mm, Angular +/- 12.5 º | |

| DN350-14″ | 216 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 51 mm, Lateral +/- 30 mm, Angular +/- 15 º | |

| DN350-14″ | 246 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 59.5 mm, Lateral +/- 35 mm, Angular +/- 17.5 º | |

| DN350-14″ | 277 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 68 mm, Lateral +/- 40 mm, Angular +/- 20 º | |

| DN350-14″ | 308 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 76.5 mm, Lateral +/- 45 mm, Angular +/- 22.5 º | |

| DN350-14″ | 338 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 85 mm, Lateral +/- 50 mm, Angular +/- 25 º | |

| DN400-16″ | 93 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 17 mm, Lateral +/- 10 mm, Angular +/- 4 º | |

| DN400-16″ | 125 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 25.5 mm, Lateral +/- 15 mm, Angular +/- 6 º | |

| DN400-16″ | 157 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 34 mm, Lateral +/- 20 mm, Angular +/- 8 º | |

| DN400-16″ | 189 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 42.5 mm, Lateral +/- 25 mm, Angular +/- 10 º | |

| DN400-16″ | 221 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 51 mm, Lateral +/- 30 mm, Angular +/- 12 º | |

| DN400-16″ | 251 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 59.5 mm, Lateral +/- 35 mm, Angular +/- 14 º | |

| DN400-16″ | 283 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 68 mm, Lateral +/- 40 mm, Angular +/- 16 º | |

| DN400-16″ | 315 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 76.5 mm, Lateral +/- 45 mm, Angular +/- 18 º | |

| DN400-16″ | 345 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 85 mm, Lateral +/- 50 mm, Angular +/- 20 º | |

| DN450-18″ | 105 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 17 mm, Lateral +/- 10 mm, Angular +/- 4 º | |

| DN450-18″ | 138 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 25.5 mm, Lateral +/- 15 mm, Angular +/- 6 º | |

| DN450-18″ | 172 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 34 mm, Lateral +/- 20 mm, Angular +/- 8 º | |

| DN450-18″ | 206 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 42.5 mm, Lateral +/- 25 mm, Angular +/- 10 º | |

| DN450-18″ | 239 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 51 mm, Lateral +/- 30 mm, Angular +/- 12 º | |

| DN450-18″ | 269 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 59.5 mm, Lateral +/- 35 mm, Angular +/- 14 º | |

| DN450-18″ | 303 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 68 mm, Lateral +/- 40 mm, Angular +/- 16 º | |

| DN500-20″ | 105 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 18 mm, Lateral +/- 11 mm, Angular +/- 4 º | |

| DN500-20″ | 138 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 27 mm, Lateral +/- 16.5 mm, Angular +/- 6 º | |

| DN500-20″ | 172 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 36 mm, Lateral +/- 22 mm, Angular +/- 8 º | |

| DN500-20″ | 206 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 45 mm, Lateral +/- 27.5 mm, Angular +/- 10 º | |

| DN500-20″ | 239 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 54 mm, Lateral +/- 33 mm, Angular +/- 12 º | |

| DN500-20″ | 273 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 63 mm, Lateral +/- 38.5 mm, Angular +/- 14 º | |

| DN500-20″ | 303 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 72 mm, Lateral +/- 44 mm, Angular +/- 16 º | |

| DN500-20″ | 336 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 81 mm, Lateral +/- 49.5 mm, Angular +/- 18 º | |

| DN500-20″ | 370 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 90 mm, Lateral +/- 55 mm, Angular +/- 20 º | |

| DN600-24″ | 105 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 18 mm, Lateral +/- 11 mm, Angular +/- 3 º | |

| DN600-24″ | 139 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 27 mm, Lateral +/- 16.5 mm, Angular +/- 4.5 º | |

| DN600-24″ | 173 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 36 mm, Lateral +/- 22 mm, Angular +/- 6 º | |

| DN600-24″ | 207 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 45 mm, Lateral +/- 27.5 mm, Angular +/- 7.5 º | |

| DN600-24″ | 241 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 54 mm, Lateral +/- 33 mm, Angular +/- 9 º | |

| DN600-24″ | 274 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 63 mm, Lateral +/- 38.5 mm, Angular +/- 10.5 º | |

| DN600-24″ | 304 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 72 mm, Lateral +/- 44 mm, Angular +/- 12 º | |

| DN600-24″ | 338 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 81 mm, Lateral +/- 49.5 mm, Angular +/- 13.5 º | |

| DN600-24″ | 372 | 2.5 Barg @ 50 ºC to 0.5 Barg @ 200 ºC | Axial +/- 90 mm, Lateral +/- 55 mm, Angular +/- 15 º | |

PTFE BELLOWS – HEAVY DUTY:

| SIZE | LENGTH | PRESSURE RATING | MOVEMENT | IN SHOP |

|---|---|---|---|---|

| DN25-1″ | 44 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 6 mm, Lateral +/- 4 mm, Angular +/- 9 º | |

| DN25-1″ | 56 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 9 mm, Lateral +/- 6 mm, Angular +/- 13.5 º | |

| DN25-1″ | 69 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 12 mm, Lateral +/- 8 mm, Angular +/- 18 º | |

| DN25-1″ | 81 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 15 mm, Lateral +/- 10 mm, Angular +/- 22.5 º | |

| DN25-1″ | 93 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 18 mm, Lateral +/- 12 mm, Angular +/- 27 º | |

| DN25-1″ | 106 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 21 mm, Lateral +/- 14 mm, Angular +/- 31.5 º | |

| DN25-1″ | 118 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 24 mm, Lateral +/- 16 mm, Angular +/- 36 º | |

| DN25-1″ | 130 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 27 mm, Lateral +/- 18 mm, Angular +/- 40.5 º | |

| DN25-1″ | 142 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 30 mm, Lateral +/- 20 mm, Angular +/- 45 º | |

| DN32-1¼” | 53 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 6 mm, Lateral +/- 4 mm, Angular +/- 8 º | |

| DN32-1¼” | 68 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 9 mm, Lateral +/- 6 mm, Angular +/- 12 º | |

| DN32-1¼” | 83 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 12 mm, Lateral +/- 8 mm, Angular +/- 16 º | |

| DN32-1¼” | 98 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 15 mm, Lateral +/- 10 mm, Angular +/- 20 º | |

| DN32-1¼” | 113 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 18 mm, Lateral +/- 12 mm, Angular +/- 24 º | |

| DN32-1¼” | 129 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 21 mm, Lateral +/- 14 mm, Angular +/- 28 º | |

| DN32-1¼” | 144 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 24 mm, Lateral +/- 16 mm, Angular +/- 32 º | |

| DN32-1¼” | 159 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 27 mm, Lateral +/- 18 mm, Angular +/- 36 º | |

| DN32-1¼” | 174 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 30 mm, Lateral +/- 20 mm, Angular +/- 40 º | |

| DN40-1½” | 54 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 7 mm, Lateral +/- 5 mm, Angular +/- 8 º | |

| DN40-1½” | 70 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 10.5 mm, Lateral +/- 7.5 mm, Angular +/- 12 º | |

| DN40-1½” | 86 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 14 mm, Lateral +/- 10 mm, Angular +/- 16 º | |

| DN40-1½” | 102 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 17.5 mm, Lateral +/- 12.5 mm, Angular +/- 20 º | |

| DN40-1½” | 119 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 21 mm, Lateral +/- 15 mm, Angular +/- 24 º | |

| DN40-1½” | 135 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 24.5 mm, Lateral +/- 17.5 mm, Angular +/- 28 º | |

| DN40-1½” | 151 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 28 mm, Lateral +/- 20 mm, Angular +/- 32 º | |

| DN40-1½” | 167 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 31.5 mm, Lateral +/- 22.5 mm, Angular +/- 36 º | |

| DN40-1½” | 183 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 35 mm, Lateral +/- 25 mm, Angular +/- 40 º | |

| DN50-2″ | 54 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 7 mm, Lateral +/- 5 mm, Angular +/- 7 º | |

| DN50-2″ | 71 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 10.5 mm, Lateral +/- 7.5 mm, Angular +/- 10.5 º | |

| DN50-2″ | 87 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 14 mm, Lateral +/- 10 mm, Angular +/- 14 º | |

| DN50-2″ | 103 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 17.5 mm, Lateral +/- 12.5 mm, Angular +/- 17.5 º | |

| DN50-2″ | 119 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 21 mm, Lateral +/- 15 mm, Angular +/- 21 º | |

| DN50-2″ | 135 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 24.5 mm, Lateral +/- 17.5 mm, Angular +/- 24.5 º | |

| DN50-2″ | 151 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 28 mm, Lateral +/- 20 mm, Angular +/- 28 º | |

| DN50-2″ | 167 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 31.5 mm, Lateral +/- 22.5 mm, Angular +/- 31.5 º | |

| DN50-2″ | 183 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 35 mm, Lateral +/- 25 mm, Angular +/- 35 º | |

| DN65-2½” | 60 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 8 mm, Lateral +/- 6 mm, Angular +/- 7 º | |

| DN65-2½” | 81 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 12 mm, Lateral +/- 9 mm, Angular +/- 10.5 º | |

| DN65-2½” | 103 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 16 mm, Lateral +/- 12 mm, Angular +/- 14 º | |

| DN65-2½” | 124 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 20 mm, Lateral +/- 15 mm, Angular +/- 17.5 º | |

| DN65-2½” | 145 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 24 mm, Lateral +/- 18 mm, Angular +/- 21 º | |

| DN65-2½” | 167 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 28 mm, Lateral +/- 21 mm, Angular +/- 24.5 º | |

| DN65-2½” | 188 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 32 mm, Lateral +/- 24 mm, Angular +/- 28 º | |

| DN65-2½” | 210 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 36 mm, Lateral +/- 27 mm, Angular +/- 31.5 º | |

| DN65-2½” | 231 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 40 mm, Lateral +/- 30 mm, Angular +/- 35 º | |

| DN80-3″ | 64 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 8 mm, Lateral +/- 6 mm, Angular +/- 7 º | |

| DN80-3″ | 89 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 12 mm, Lateral +/- 9 mm, Angular +/- 10.5 º | |

| DN80-3″ | 115 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 16 mm, Lateral +/- 12 mm, Angular +/- 14 º | |

| DN80-3″ | 140 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 20 mm, Lateral +/- 15 mm, Angular +/- 17.5 º | |

| DN80-3″ | 165 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 24 mm, Lateral +/- 18 mm, Angular +/- 21 º | |

| DN80-3″ | 190 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 28 mm, Lateral +/- 21 mm, Angular +/- 24.5 º | |

| DN80-3″ | 215 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 32 mm, Lateral +/- 24 mm, Angular +/- 28 º | |

| DN80-3″ | 240 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 36 mm, Lateral +/- 27 mm, Angular +/- 31.5 º | |

| DN80-3″ | 265 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 40 mm, Lateral +/- 30 mm, Angular +/- 35 º | |

| DN100-4″ | 66 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 9 mm, Lateral +/- 6 mm, Angular +/- 6 º | |

| DN100-4″ | 92 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 13.5 mm, Lateral +/- 9 mm, Angular +/- 9 º | |

| DN100-4″ | 119 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 18 mm, Lateral +/- 12 mm, Angular +/- 12 º | |

| DN100-4″ | 145 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 22.5 mm, Lateral +/- 15 mm, Angular +/- 15 º | |

| DN100-4″ | 171 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 27 mm, Lateral +/- 18 mm, Angular +/- 18 º | |

| DN100-4″ | 198 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 31.5 mm, Lateral +/- 21 mm, Angular +/- 21 º | |

| DN100-4″ | 224 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 36 mm, Lateral +/- 24 mm, Angular +/- 24 º | |

| DN100-4″ | 250 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 40.5 mm, Lateral +/- 27 mm, Angular +/- 27 º | |

| DN100-4″ | 276 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 45 mm, Lateral +/- 30 mm, Angular +/- 30 º | |

| DN125-5″ | 77 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 9 mm, Lateral +/- 6 mm, Angular +/- 6 º | |

| DN125-5″ | 103 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 13.5 mm, Lateral +/- 9 mm, Angular +/- 9 º | |

| DN125-5″ | 129 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 18 mm, Lateral +/- 12 mm, Angular +/- 12 º | |

| DN125-5″ | 154 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 22.5 mm, Lateral +/- 15 mm, Angular +/- 15 º | |

| DN125-5″ | 180 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 27 mm, Lateral +/- 18 mm, Angular +/- 18 º | |

| DN125-5″ | 206 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 31.5 mm, Lateral +/- 21 mm, Angular +/- 21 º | |

| DN125-5″ | 231 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 36 mm, Lateral +/- 24 mm, Angular +/- 24 º | |

| DN125-5″ | 257 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 40.5 mm, Lateral +/- 27 mm, Angular +/- 27 º | |

| DN125-5″ | 283 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 45 mm, Lateral +/- 30 mm, Angular +/- 30 º | |

| DN150-6″ | 78 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 10 mm, Lateral +/- 6 mm, Angular +/- 5 º | |

| DN150-6″ | 105 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 15 mm, Lateral +/- 9 mm, Angular +/- 7.5 º | |

| DN150-6″ | 133 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 20 mm, Lateral +/- 12 mm, Angular +/- 10 º | |

| DN150-6″ | 158 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 25 mm, Lateral +/- 15 mm, Angular +/- 12.5 º | |

| DN150-6″ | 185 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 30 mm, Lateral +/- 18 mm, Angular +/- 15 º | |

| DN150-6″ | 212 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 35 mm, Lateral +/- 21 mm, Angular +/- 17.5 º | |

| DN150-6″ | 237 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 40 mm, Lateral +/- 24 mm, Angular +/- 20 º | |

| DN150-6″ | 264 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 45 mm, Lateral +/- 27 mm, Angular +/- 22.5 º | |

| DN150-6″ | 291 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 50 mm, Lateral +/- 30 mm, Angular +/- 25 º | |

| DN200-8″ | 80 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 10 mm, Lateral +/- 7 mm, Angular +/- 4 º | |

| DN200-8″ | 108 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 15 mm, Lateral +/- 10.5 mm, Angular +/- 6 º | |

| DN200-8″ | 136 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 20 mm, Lateral +/- 14 mm, Angular +/- 8 º | |

| DN200-8″ | 164 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 25 mm, Lateral +/- 17.5 mm, Angular +/- 10 º | |

| DN200-8″ | 189 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 30 mm, Lateral +/- 21 mm, Angular +/- 12 º | |

| DN200-8″ | 217 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 35 mm, Lateral +/- 24.5 mm, Angular +/- 14 º | |

| DN200-8″ | 245 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 40 mm, Lateral +/- 28 mm, Angular +/- 16 º | |

| DN200-8″ | 270 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 45 mm, Lateral +/- 31.5 mm, Angular +/- 18 º | |

| DN200-8″ | 298 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 50 mm, Lateral +/- 35 mm, Angular +/- 20 º | |

| DN250-10″ | 81 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 11 mm, Lateral +/- 7 mm, Angular +/- 4 º | |

| DN250-10″ | 110 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 16.5 mm, Lateral +/- 10.5 mm, Angular +/- 6 º | |

| DN250-10″ | 140 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 22 mm, Lateral +/- 14 mm, Angular +/- 8 º | |

| DN250-10″ | 169 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 27.5 mm, Lateral +/- 17.5 mm, Angular +/- 10 º | |

| DN250-10″ | 199 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 33 mm, Lateral +/- 21 mm, Angular +/- 12 º | |

| DN250-10″ | 228 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 38.5 mm, Lateral +/- 24.5 mm, Angular +/- 14 º | |

| DN250-10″ | 257 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 44 mm, Lateral +/- 28 mm, Angular +/- 16 º | |

| DN250-10″ | 287 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 49.5 mm, Lateral +/- 31.5 mm, Angular +/- 18 º | |

| DN250-10″ | 316 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 55 mm, Lateral +/- 35 mm, Angular +/- 20 º | |

| DN300-12″ | 83 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 11 mm, Lateral +/- 7 mm, Angular +/- 3 º | |

| DN300-12″ | 113 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 16.5 mm, Lateral +/- 10.5 mm, Angular +/- 4.5 º | |

| DN300-12″ | 143 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 22 mm, Lateral +/- 14 mm, Angular +/- 6 º | |

| DN300-12″ | 173 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 27.5 mm, Lateral +/- 17.5 mm, Angular +/- 7.5 º | |

| DN300-12″ | 203 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 33 mm, Lateral +/- 21 mm, Angular +/- 9 º | |

| DN300-12″ | 233 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 38.5 mm, Lateral +/- 24.5 mm, Angular +/- 10.5 º | |

| DN300-12″ | 264 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 44 mm, Lateral +/- 28 mm, Angular +/- 12 º | |

| DN300-12″ | 294 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 49.5 mm, Lateral +/- 31.5 mm, Angular +/- 13.5 º | |

| DN300-12″ | 324 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 55 mm, Lateral +/- 35 mm, Angular +/- 15 º | |

| DN350-14″ | 94 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 12 mm, Lateral +/- 7 mm, Angular +/- 3 º | |

| DN350-14″ | 125 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 18 mm, Lateral +/- 10.5 mm, Angular +/- 4.5 º | |

| DN350-14″ | 157 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 24 mm, Lateral +/- 14 mm, Angular +/- 6 º | |

| DN350-14″ | 188 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 30 mm, Lateral +/- 17.5 mm, Angular +/- 7.5 º | |

| DN350-14″ | 219 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 36 mm, Lateral +/- 21 mm, Angular +/- 9 º | |

| DN350-14″ | 249 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 42 mm, Lateral +/- 24.5 mm, Angular +/- 10.5 º | |

| DN350-14″ | 280 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 48 mm, Lateral +/- 28 mm, Angular +/- 12 º | |

| DN350-14″ | 311 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 54 mm, Lateral +/- 31.5 mm, Angular +/- 13.5 º | |

| DN350-14″ | 341 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 60 mm, Lateral +/- 35 mm, Angular +/- 15 º | |

| DN400-16″ | 96 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 12 mm, Lateral +/- 7 mm, Angular +/- 3 º | |

| DN400-16″ | 128 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 18 mm, Lateral +/- 10.5 mm, Angular +/- 4.5 º | |

| DN400-16″ | 160 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 24 mm, Lateral +/- 14 mm, Angular +/- 6 º | |

| DN400-16″ | 192 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 30 mm, Lateral +/- 17.5 mm, Angular +/- 7.5 º | |

| DN400-16″ | 224 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 36 mm, Lateral +/- 21 mm, Angular +/- 9 º | |

| DN400-16″ | 254 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 42 mm, Lateral +/- 24.5 mm, Angular +/- 10.5 º | |

| DN400-16″ | 286 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 48 mm, Lateral +/- 28 mm, Angular +/- 12 º | |

| DN400-16″ | 318 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 54 mm, Lateral +/- 31.5 mm, Angular +/- 13.5 º | |

| DN400-16″ | 348 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 60 mm, Lateral +/- 35 mm, Angular +/- 15 º | |

| DN450-18″ | 108 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 12 mm, Lateral +/- 7 mm, Angular +/- 3 º | |

| DN450-18″ | 141 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 18 mm, Lateral +/- 10.5 mm, Angular +/- 4.5 º | |

| DN450-18″ | 175 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 24 mm, Lateral +/- 14 mm, Angular +/- 6 º | |

| DN450-18″ | 209 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 30 mm, Lateral +/- 17.5 mm, Angular +/- 7.5 º | |

| DN450-18″ | 243 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 36 mm, Lateral +/- 21 mm, Angular +/- 9 º | |

| DN450-18″ | 273 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 42 mm, Lateral +/- 24.5 mm, Angular +/- 10.5 º | |

| DN450-18″ | 306 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 48 mm, Lateral +/- 28 mm, Angular +/- 12 º | |

| DN500-20″ | 108 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 13 mm, Lateral +/- 8 mm, Angular +/- 3 º | |

| DN500-20″ | 142 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 19.5 mm, Lateral +/- 12 mm, Angular +/- 4.5 º | |

| DN500-20″ | 175 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 26 mm, Lateral +/- 16 mm, Angular +/- 6 º | |

| DN500-20″ | 209 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 32.5 mm, Lateral +/- 20 mm, Angular +/- 7.5 º | |

| DN500-20″ | 243 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 39 mm, Lateral +/- 24 mm, Angular +/- 9 º | |

| DN500-20″ | 276 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 45.5 mm, Lateral +/- 28 mm, Angular +/- 10.5 º | |

| DN500-20″ | 306 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 52 mm, Lateral +/- 32 mm, Angular +/- 12 º | |

| DN500-20″ | 340 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 58.5 mm, Lateral +/- 36 mm, Angular +/- 13.5 º | |

| DN500-20″ | 373 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 65 mm, Lateral +/- 40 mm, Angular +/- 15 º | |

| DN600-24″ | 109 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 13 mm, Lateral +/- 8 mm, Angular +/- 2 º | |

| DN600-24″ | 143 | 16 Barg @ 50 ºC to 3 Barg @ 235 ºC | Axial +/- 19.5 mm, Lateral +/- 12 mm, Angular +/- 3 º | |

| DN600-24″ | 177 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 26 mm, Lateral +/- 16 mm, Angular +/- 4 º | |

| DN600-24″ | 210 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 32.5 mm, Lateral +/- 20 mm, Angular +/- 5 º | |

| DN600-24″ | 244 | 10 Barg @ 50 ºC to 2 Barg @ 235 ºC | Axial +/- 39 mm, Lateral +/- 24 mm, Angular +/- 6 º | |

| DN600-24″ | 278 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 45.5 mm, Lateral +/- 28 mm, Angular +/- 7 º | |

| DN600-24″ | 308 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 52 mm, Lateral +/- 32 mm, Angular +/- 8 º | |

| DN600-24″ | 342 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 58.5 mm, Lateral +/- 36 mm, Angular +/- 9 º | |

| DN600-24″ | 376 | 6 Barg @ 50 ºC to 1 Barg @ 235 ºC | Axial +/- 65 mm, Lateral +/- 40 mm, Angular +/- 10 º |

How to Select PTFE Expansion Bellow

Temperature is the most critical selection factor as the mechanical strength of PTFE decreases rapidly with increasing pressure. Note that due to the limited strength of PTFE the number of convolutions also strongly influences the rating of the bellows, we provide data for 2-3, 4-6 and 7-10 convolution bellows. The Heavy Duty bellows have a higher pressure rating but a lower range of allowable movements.

Temperature is the most critical selection factor as the mechanical strength of PTFE decreases rapidly with increasing pressure. Note that due to the limited strength of PTFE the number of convolutions also strongly influences the rating of the bellows, we provide data for 2-3, 4-6 and 7-10 convolution bellows. The Heavy Duty bellows have a higher pressure rating but a lower range of allowable movements. PTFE is almost totally chemically inert and highly insoluble in most solvents or chemicals. This makes it an excellent choice in highly corrosive environments or where media contamination is an issue. However where the temperature and mechanical strength of a PTFE bellows is a problem other materials – or a PTFE liner in another type of bellows – may be a better solution, see our Bellows Finder.

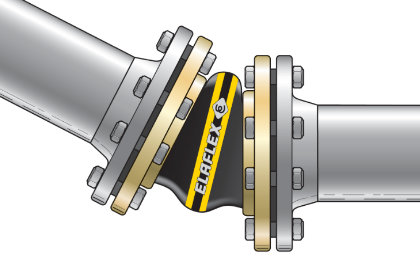

PTFE is almost totally chemically inert and highly insoluble in most solvents or chemicals. This makes it an excellent choice in highly corrosive environments or where media contamination is an issue. However where the temperature and mechanical strength of a PTFE bellows is a problem other materials – or a PTFE liner in another type of bellows – may be a better solution, see our Bellows Finder. Standard diameters between DN25 and DN600 in 2-10 convolutions, fixed lengths. For larger diameters and other lengths the Safetech rubber bellows range can be specified with a PTFE liner

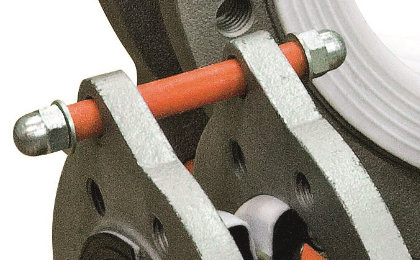

Standard diameters between DN25 and DN600 in 2-10 convolutions, fixed lengths. For larger diameters and other lengths the Safetech rubber bellows range can be specified with a PTFE liner Any flange drilling can be supplied; if you are uncertain about what you already have installed our Flange Finder will help you identify it. PTFE bellows have Van Stone flanges (see FAQ) with limit rods to prevent over extension. The bellows will exert a pressure force on the pipe (see FAQ) which must be restrained or absorbed at the piping anchors.

Any flange drilling can be supplied; if you are uncertain about what you already have installed our Flange Finder will help you identify it. PTFE bellows have Van Stone flanges (see FAQ) with limit rods to prevent over extension. The bellows will exert a pressure force on the pipe (see FAQ) which must be restrained or absorbed at the piping anchors. PTFE bellows have a defined movement range, which is shown for each type in the Range tab on this page. The movements listed are non-concurrent (see FAQ).

PTFE bellows have a defined movement range, which is shown for each type in the Range tab on this page. The movements listed are non-concurrent (see FAQ). Call our expert team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.

Call our expert team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.FlexEJ’s PTFE Expansion Bellows

FlexEJ has the following two ranges of PTFE joints available:

STANDARD DUTY PTFE BELLOWS

2-3, 4-6 and 7-10 convolutions, inert, highly compatible

Solid PTFE multilayer convolutions assure minimum permeability and good mechanical performance. Rated from 10 Barg at 50°C, the pressure rating reduces with both increasing temperature and number of convolutions, please see the range charts. Supplied with flanges which can be specified to any drilling pattern in coated carbon steel or stainless steel. Flanges are Van Stone which guarantees that the media is only ever in contact with PTFE. Limit rods are provided to prevent over extension.

HEAVY DUTY PTFE BELLOWS

2-3, 4-6 and 7-10 convolutions, inert, highly compatible

Solid PTFE multilayer convolutions assure minimum permeability and good mechanical performance. Rated from 16 Barg at 50°C, the pressure rating reduces with both increasing temperature and number of convolutions, please see the range charts. Supplied with flanges which can be specified to any drilling pattern in coated carbon steel or stainless steel. Flanges are Van Stone which guarantees that the media is only ever in contact with PTFE. Limit rods are provided to prevent over extension.

Can't see what you want? Need help?

Call us. Or use Live Chat.

For instant advice. We can custom-design and engineer almost any expansion joint you need for delivery in the UK or worldwide. Call our expert team on +44 (0) 1384 881188 Or email us sales@flexej.co.uk

Frequently Asked Questions

A. A tie rod is a simple pressure thrust restraint. It will allow reasonable lateral movement but not axial extension; it can allow axial compression if the pressure thrust is overcome by the piping movement. See the movements and pressure thrust FAQs for definitions. For technical assistance please contact us or use our Live Chat facility.

A. All expansion joints exert a force, pushing the pipe ends apart – pressure thrust – which is proportional to the operating pressure and diameter of the bellows. If the expansion joint is unrestrained the piping system must withstand the force, or, alternatively, the expansion joint may have restraints built in to constrain the pressure thrust force. For instance types, tie rod, hinge or gimbal. For technical assistance please contact us or use our Live Chat facility.

A. To design or select a rubber bellows or metal expansion joint we need to know: nominal bore, end type, service, temperature, pressure and required movements. You may also specify in addition your requirements for external hardware – tie rods, hinges, gimbals – internal liner, external cover and instrumentation. Material selections should also be specified to suit the service and associated system piping. For technical assistance please contact us or use our Live Chat facility.

A. The EJMA is the Expansion Joints Manufacturers Association. Their bellows calculation method is most frequently used for metal bellows expansion joint design. EJMA does not cover rubber bellows or metal hose design. For technical assistance please contact us or use the LIVE CHAT link on this page.