ELAFLEX. PREMIUM-QUALITY RUBBER EXPANSION BELLOWS

Manufactured in Germany, Elaflex RedBand rubber bellows are high-quality, durable rubber expansion joints that have thousands of configuration options from DN25 to DN1000.

24hr Shipping

On all stock items ordered.

Mon-Thur by 2pm, 10am Fridays

Design & Manufacturing

Full in-house design & manufacture to EN / ASME / PED.

ISO14001 Accreditation

FlexEJ has an accredited Environmental Management System.

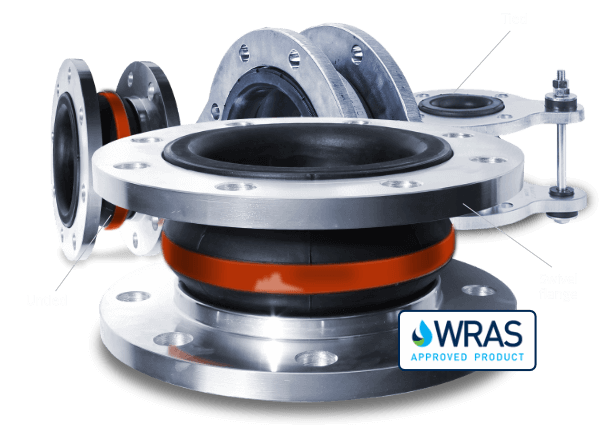

Elaflex RedBand ERV-R Rubber Bellows

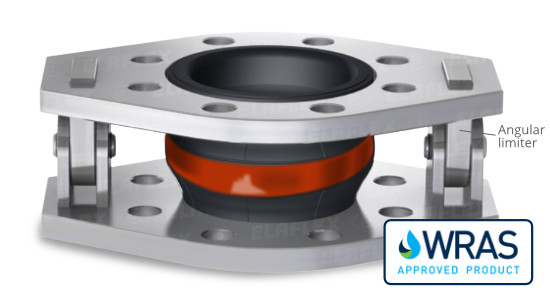

The Elaflex RedBand ERV-R rubber bellows features a Butyl (IIR) / EPDM, seamless, low permeation liner with PA textile cord, Butyl rubberized reinforcement and EPDM, ozone proof, heat resistant cover.

RedBand ERV-R Rubber Bellows are suitable for drinking water, cold and warm waste water, seawater, cooling water, water with chemical additives, low concentrated acids and alkalis, salt solutions, technical alcohols, esters and ketones and are available from DN25 to DN1000 with a wide choice of configuration, flange and restraint options.

PRODUCT GUIDES

ELAFLEX RUBBER BELLOWS

WHAT IS AN ELAFLEX REDBAND ERV-R RUBBER BELLOWS?

WRAS APPROVED FOR DRINKING WATER…

Materials

EPDM with carbon steel flanges or cast iron unions.

Application

Water: drinking, LT and HT heating, waste, sanitary, chilled with tied or untied flanges or unions.

Rating

Wide range to suit all applications PN10, PN16 and temperatures to +130°C.

WEB SHOP

Available online with next day delivery from our web shop.

ELAFLEX REDBAND ERV-R RUBBER BELLOWS

| SIZE | LENGTH | PRESSURE RATING | MOVEMENT | IN SHOP |

|---|---|---|---|---|

| DN25-1″ | 130mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +20/-30 mm, Lateral +/- 30 mm, Angular +/- 30º | |

| DN32-1¼” | 130mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +20/-30 mm, Lateral +/- 30 mm, Angular +/- 30º | Yes |

| DN32-1¼” | 160mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +35/-30 mm, Lateral +/- 35 mm, Angular +/- 15º | |

| DN40-1½” | 130mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +20/-30 mm, Lateral +/- 30 mm, Angular +/- 30º | Yes |

| DN40-1½” | 160mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +35/-30 mm, Lateral +/- 35 mm, Angular +/- 15º | |

| DN50-2″ | 130mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +20/-30 mm, Lateral +/- 30 mm, Angular +/- 30º | Yes |

| DN50-2″ | 150mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +30/-35 mm, Lateral +/- 30 mm, Angular +/- 15º | |

| DN50-2″ | 160mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +35/-30 mm, Lateral +/- 35 mm, Angular +/- 15º | |

| DN65-2½” | 130mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +20/-30 mm, Lateral +/- 30 mm, Angular +/- 30º | Yes |

| DN65-2½” | 150mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +30/-35 mm, Lateral +/- 30 mm, Angular +/- 15º | |

| DN65-2½” | 160mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +35/-30 mm, Lateral +/- 35 mm, Angular +/- 15º | |

| DN80-3″ | 130mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +20/-30 mm, Lateral +/- 30 mm, Angular +/- 30º | Yes |

| DN80-3″ | 150mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +30/-35 mm, Lateral +/- 30 mm, Angular +/- 15º | |

| DN80-3″ | 160mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +35/-30 mm, Lateral +/- 35 mm, Angular +/- 15º | |

| DN100-4″ | 130mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +20/-30 mm, Lateral +/- 30 mm, Angular +/- 20º | Yes |

| DN100-4″ | 150mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +30/-35 mm, Lateral +/- 30 mm, Angular +/- 15º | |

| DN100-4″ | 160mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +35/-30 mm, Lateral +/- 35 mm, Angular +/- 15º | |

| DN125-5″ | 130mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +20/-30 mm, Lateral +/- 30 mm, Angular +/- 20º | Yes |

| DN125-5″ | 150mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +30/-35 mm, Lateral +/- 30 mm, Angular +/- 15º | |

| DN125-5″ | 160mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +35/-30 mm, Lateral +/- 35 mm, Angular +/- 15º | |

| DN150-6″ | 130mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +20/-30 mm, Lateral +/- 30 mm, Angular +/- 20º | Yes |

| DN150-6″ | 150mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +30/-35 mm, Lateral +/- 30 mm, Angular +/- 15º | |

| DN150-6″ | 160mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +35/-30 mm, Lateral +/- 35 mm, Angular +/- 15º | |

| DN200-8″ | 130mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +30/-25 mm, Lateral +/- 30 mm, Angular +/- 10º | |

| DN200-8″ | 150mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +30/-35 mm, Lateral +/- 30 mm, Angular +/- 15º | |

| DN200-8″ | 160mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +35/-30 mm, Lateral +/- 35 mm, Angular +/- 15º | |

| DN200-8″ | 175mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +35/-15 mm, Lateral +/- 15 mm, Angular +/- 5º | |

| DN250-10″ | 130mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +30/-10 mm, Lateral +/- 15 mm, Angular +/- 5º | |

| DN250-10″ | 175mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +35/-15 mm, Lateral +/- 10 mm, Angular +/- 5º | |

| DN250-10″ | 200mm | 10 Barg @ 50 ºC to 6 Barg @ 100 ºC | Axial +35/-40 mm, Lateral +/- 30 mm, Angular +/- 10º | |

| DN300-12″ | 130mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +30/-10 mm, Lateral +/- 15 mm, Angular +/- 5º | |

| DN300-12″ | 200mm | 10 Barg @ 50 ºC to 6 Barg @ 100 ºC | Axial +35/-40 mm, Lateral +/- 30 mm, Angular +/- 10º | |

| DN350-14″ | 200mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +35/-40 mm, Lateral +/- 30 mm, Angular +/- 8º | |

| DN400-16″ | 200mm | 16 Barg @ 50 ºC to 10 Barg @ 100 ºC | Axial +35/-40 mm, Lateral +/- 30 mm, Angular +/- 8º | |

| DN450-18″ | 200mm | 10 Barg @ 50 ºC to 6 Barg @ 100 ºC | Axial +35/-40 mm, Lateral +/- 30 mm, Angular +/- 8º | |

| DN450-18″ | 250mm | 10 Barg @ 50 ºC to 6 Barg @ 100 ºC | Axial +35/-40 mm, Lateral +/- 35 mm, Angular +/- 10º | |

| DN500-20″ | 200mm | 10 Barg @ 50 ºC to 6 Barg @ 100 ºC | Axial +35/-40 mm, Lateral +/- 30 mm, Angular +/- 8º | |

| DN600-24″ | 200mm | 10 Barg @ 50 ºC to 6 Barg @ 100 ºC | Axial +35/-40 mm, Lateral +/- 30 mm, Angular +/- 8º | |

| DN700-28″ | 260mm | 10 Barg @ 50 ºC to 6 Barg @ 100 ºC | Axial +30/-40 mm, Lateral +/- 30 mm, Angular +/- 5º | |

| DN800-32″ | 250mm | 10 Barg @ 50 ºC to 6 Barg @ 100 ºC | Axial +35/-40 mm, Lateral +/- 35 mm, Angular +/- 5º | |

| DN900-36″ | 300mm | 10 Barg @ 50 ºC to 6 Barg @ 100 ºC | Axial +40/-40 mm, Lateral +/- 40 mm, Angular +/- 5º | |

| DN1000-40″ | 300mm | 10 Barg @ 50 ºC to 6 Barg @ 100 ºC | Axial +40/-40 mm, Lateral +/- 40 mm, Angular +/- 5º |

How to select a RedBand ERV-R Rubber Bellow

Temperature is the most critical as it directly influences the choice of rubber – but also the actual pressure capability of the bellows. The stated maximum rated pressure is maintained up to around 50ºC for most rubber bellows, for higher temperatures check the data in the Range tab.

Temperature is the most critical as it directly influences the choice of rubber – but also the actual pressure capability of the bellows. The stated maximum rated pressure is maintained up to around 50ºC for most rubber bellows, for higher temperatures check the data in the Range tab. The rubber compound used for the inner layer of the bellows must be compatible with the working fluid. Drinking water requires a WRAS approved EPDM, oils require Nitrile and so on – our Bellows Finder can help you with finding the right rubber.

The rubber compound used for the inner layer of the bellows must be compatible with the working fluid. Drinking water requires a WRAS approved EPDM, oils require Nitrile and so on – our Bellows Finder can help you with finding the right rubber. Moulded bellows are manufactured in set combinations of diameters and lengths. However, our handmade Safetech range can be manufactured in any diameter and length to suit your application, only the more standard sizes are shown on the Safetech range tab.

Moulded bellows are manufactured in set combinations of diameters and lengths. However, our handmade Safetech range can be manufactured in any diameter and length to suit your application, only the more standard sizes are shown on the Safetech range tab. Any flange drilling can be supplied; if you are uncertain about what you already have installed our Flange Finder will help you identify it. The HVAC and Elaflex ranges have swivel flanges; the Safetech range has full face rubber flanges. Our web shop stock is PN10/16. Bellows will exert a pressure force on the pipe (see FAQ) which must be restrained or absorbed at the piping anchors. All our flanged rubber expansion joints are available with tie rods and we can offer hinges or gimbals on the Elaflex and Safetech products.

Any flange drilling can be supplied; if you are uncertain about what you already have installed our Flange Finder will help you identify it. The HVAC and Elaflex ranges have swivel flanges; the Safetech range has full face rubber flanges. Our web shop stock is PN10/16. Bellows will exert a pressure force on the pipe (see FAQ) which must be restrained or absorbed at the piping anchors. All our flanged rubber expansion joints are available with tie rods and we can offer hinges or gimbals on the Elaflex and Safetech products. Moulded rubber bellows have a defined movement range, which is shown for each type in the Range tab, movements listed are non-concurrent (see FAQ). A Safetech bellows will be designed to meet your required movements.

Moulded rubber bellows have a defined movement range, which is shown for each type in the Range tab, movements listed are non-concurrent (see FAQ). A Safetech bellows will be designed to meet your required movements. Call our expert team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.

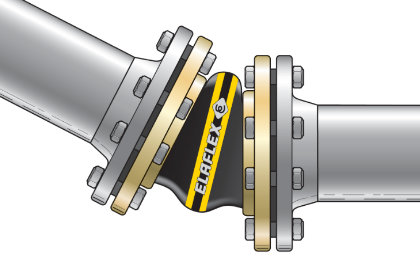

Call our expert team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.Elaflex RedBand ERV-R Restraint options

FlexEJ has the following tie rod restraint options in stock for the RedBand ERV-R Rubber Bellows range. Angular and more advanced configurations can be engineered to your exact requirements, however complex. Just let us know what you have in mind.

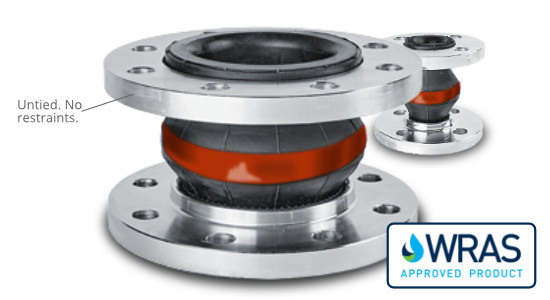

Without Restraints

(Untied)

WITHOUT RESTRAINTS

No movement restriction, pressure force acts on pipe The bellows will exert a pressure force on the pipe (see FAQ) as the bellows tries to elongate which must be absorbed at the piping anchors. Any equipment connected to the bellows must have an adequate flange load rating.Tie rods with outer nuts

(Tied)

TIE RODS WITH OUTER NUTS

No axial extension, pressure force restrained Tie rods with outer nuts only restrict the elongation of the bellows under pressure and restrains the pressure force. Up to DN300 the tie bars lie elastically in noise-reducing rubber bushes of weatherproof rubber, from DN350 steel spherical washers are provided. The bellows can move laterally. Axial compression is also possible but only if the piping overcomes the pressure force.Tie rods with inner and outer nuts

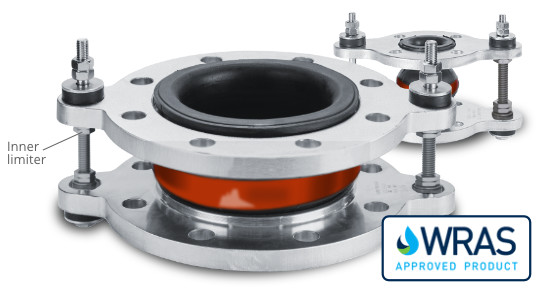

(Lateral only)

TIE RODS WITH INNER AND OUTER NUTS

No axial extension or compression, pressure force restrained Tie rods with inner and outer nuts both restrict the elongation of the bellows under pressure (restrains the pressure force) and limits axial compression. Up to DN300 the tie bars lie elastically in noise-reducing rubber bushes of weatherproof rubber, from DN350 steel spherical washers are provided. The bellows can move laterally. Axial compression is also possible but only if the piping overcomes the pressure force and a gap is set between the inner nuts and the flange.Hinges

(Angular only)

HINGES

Angular movement only, pressure force restrained The hinge restricts bellows movement to angular only. The pressure force is restrained by the hinge. No axial or lateral movement is possible. Two hinged bellows working together can form a very effective restrained lateral joint with low spring rate capable of very large movements.Elaflex RedBand ERV Finders and Calculators

We have a couple of easy to use tools and calculators to help you resource the best Elaflex expansion bellows from our next-day delivery stock items. Our Thermal Expansion Calculator for Piping helps you estimate the increase in length of a pipe run with temperature.

Our Advanced Bellows Finder is a quick way to navigate our on-line Elaflex stock range of expansion bellows and joints – with 24hr delivery across the UK. With just a few choices you can arrive at the appropriate selection – criteria include pipe size, type, media compatibility, installation length, pressure rating, pipe connection type, conformance and movement axial, lateral and angular. All the products are in the online store with 24hr shipping as standard. If you’re not sure what flange you need, our handy Flange Finder should also be useful.Stock RedBand ERV-R Rubber Bellows Finder

Do search for Elaflex RedBand expansion bellows by pipe size, intended media and/or connection hardware to see FlexEJ’s stock Elaflex bellows options below but don’t hesitate to call us on 01384 881188 or email us for more bespoke options, sizes and restraint configurations or technical advice.

Can't quite find the right bellow?

Try our Advanced Bellows Finder

Or call our expert team on +44 (0) 1384 881188. We'll be glad to help.

RedBand ERV-R comparison chart

Is the RedBand ERV-R the best option for your application? Three potential alternatives to consider:

WRAS approved  WRAS approved bellows

WRAS approved bellows

Is this bellow approved for use in all UK public mains water supplies?

Potable water  Potable water

Potable water

Is this bellow approved for water systems used for drinking and food preparation?

DIN 4809 compliant  HT Heating Water DIN4809 compliant

HT Heating Water DIN4809 compliant

Is this bellow compliant with the German DIN4809 standard of approval for warm water heating systems? (Max 100°C, 10 bar).

Oily & drainage water  Oily & drainage water

Oily & drainage water

Contaminated, oily, drain & waste water. Is this bellows suitable for contaminated water services that would degrade an EPDM rubber?

Rating barg/°C  Pressure & temperature

Pressure & temperature

What is the required pressure rating (in barg) compared to temperature rating for this bellow?

Can't see what you want? Need help?

Call us. Or use Live Chat.

For instant advice. We can custom-design and engineer almost any expansion joint you need for delivery in the UK or worldwide. Call our expert team on +44 (0) 1384 881188 Or email us sales@flexej.co.uk

Frequently Asked Questions

A. Yes. FlexEJ holds a large stock of the most popular sizes and types of Elaflex rubber bellows as well as our HVAC value bellows range. We also hold stock of the most popular metal bellows for HVAC. Many of these items are available on 24hr delivery from our online web shop. We can also manufacture to order. For sales assistance please contact us or use our Live Chat facility.

A. Our Flange Finder contains details for many common flanges. Typically, to be able to make the identification you need to know the bore size or outside diameter and number of bolts. For technical assistance contact us or use our Live Chat facility.

A. Please refer to our guidelines for installation, anchoring & guides. They are available in the Downloads section of this website: Elaflex Rubber Bellows Installation Instructions and FlexEJ Metal Bellows Installation Instructions. For technical assistance please contact us or use our Live Chat facility.

A. Yes, our Elaflex ERV-R and ERP rubber bellows have WRAS, DVGW and ACS approval for drinking water. The Safetech manufactured to order rubber bellows can be supplied with WRAS approved EPDM linings. Our MRCA copper ended metal expansion joints also have WRAS approval. For technical assistance please contact us or use the LIVE CHAT link on this page.

A. The ERP Redspot, ERV-R Redband and Rotex DoubleRed bellows are now available from FLEXEJDIRECT from stock for the most common sizes and configuration of these popular high-quality bellows. The shop items and can be despatched same day (Monday to Thursday) on a 24hr service if in stock. More advanced configurations and the other nine Elaflex bellows ranges are available to assemble to exact specifications and typically take 7-10 days (depending on size, quantities and configurations required).

Please visit our full FAQ page to see all our frequently asked questions.