safetech engineered bellows

Large-diameter, high-quality, full-face rubber expansion joints for industry custom-made to your exact requirements.

24hr Shipping

On all stock items ordered.

Mon-Thur by 2pm, 10am Fridays

Design & Manufacturing

Full in-house design & manufacture to EN / ASME / PED.

ISO14001 Accreditation

FlexEJ has an accredited Environmental Management System.

Large-scale Rubber Expansion Joint Design & Manufacturing

Safetech is FlexEJ’s sister company located in Spain. Safetech designs and manufactures rubber expansion joints in their own dedicated facility near Bilbao. This ability to hand build rubber expansion joints means we can offer lengths, diameters, movements, materials, restraints and rating to meet your precise requirements.

Pressure balanced rubber expansion joints and PTFE lined rubber expansion joints are just two of the specialty products we design and manufacture.

PRODUCT GUIDES

MANUFACTURED RUBBER BELLOWS

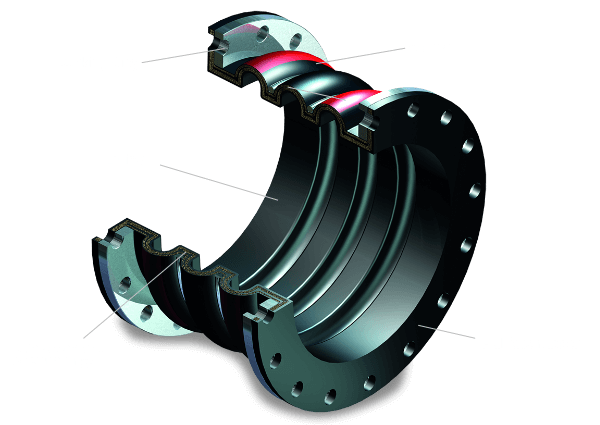

WHAT IS A SAFETECH FULL-FACE RUBBER BELLOW?

DESIGNED WITH A RUBBER FLANGE AND BACKING RING…

Materials

Full range of rubber types, backing rings in stainless steel, carbon steel – hot dipped galvanised or coated.

Application

Typically seawater, cooling water, drinking water.

Rating

Engineered to meet your exact specification in any rubber, flange drilling and length.

Approvals

WRAS (EPDM Rubbers).

Data for 1, 2, 3 and 4 arch bellows:

SAFETECH. RUBBER BELLOWS MANUFACTURING – SINGLE ARCH

| PRODUCT | SIZE | LENGTH | PRESSURE RATING | MOVEMENT |

|---|---|---|---|---|

| SingleArch | DN600-24″ | 300mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +25/-38 mm, Lateral +/- 25 mm, Angular +/- 4.4º |

| SingleArch | DN700-28″ | 300mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +25/-38 mm, Lateral +/- 25 mm, Angular +/- 4º |

| SingleArch | DN800-32″ | 300mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +25/-38 mm, Lateral +/- 25 mm, Angular +/- 4.9º |

| SingleArch | DN900-36″ | 300mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +25/-38 mm, Lateral +/- 25 mm, Angular +/- 3.4º |

| SingleArch | DN1000-40″ | 300mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 3.1º |

| SingleArch | DN1050-42″ | 300mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 3º |

| SingleArch | DN1100-44″ | 300mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 2.9º |

| SingleArch | DN1150-46″ | 300mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 2.6º |

| SingleArch | DN1200-48″ | 300mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 2.5º |

| SingleArch | DN1250-50″ | 300mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 2.5º |

| SingleArch | DN1300-52″ | 350mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 2.4º |

| SingleArch | DN1350-54″ | 350mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 2.3º |

| SingleArch | DN1400-56″ | 350mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 2.2º |

| SingleArch | DN1450-58″ | 350mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 2.1º |

| SingleArch | DN1500-60″ | 350mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 2.1º |

| SingleArch | DN1600-64″ | 350mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 2º |

| SingleArch | DN1650-66″ | 350mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.9º |

| SingleArch | DN1700-68″ | 350mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.9º |

| SingleArch | DN1800-72″ | 350mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.8º |

| SingleArch | DN1900-76″ | 350mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.5º |

| SingleArch | DN1950-78″ | 350mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.5º |

| SingleArch | DN2000-80″ | 350mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.5º |

| SingleArch | DN2100-84″ | 350mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.4º |

| SingleArch | DN2200-88″ | 350mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.4º |

| SingleArch | DN2250-90″ | 350mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.4º |

| SingleArch | DN2300-92″ | 350mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.3º |

| SingleArch | DN2400-96″ | 350mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.3º |

| SingleArch | DN2500-100″ | 350mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.2º |

| SingleArch | DN2550-102″ | 350mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.2º |

| SingleArch | DN2600-104″ | 350mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.2º |

| SingleArch | DN2700-108″ | 350mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.2º |

| SingleArch | DN2800-112″ | 350mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.1º |

| SingleArch | DN2850-114″ | 350mm | 4 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.1º |

| SingleArch | DN2900-116″ | 350mm | 4 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1.1º |

| SingleArch | DN3000-120″ | 350mm | 4 Barg (higher available) @ -40 to +140 ºC | Axial +35/-55 mm, Lateral +/- 35 mm, Angular +/- 1º |

SAFETECH. RUBBER BELLOWS MANUFACTURING – DOUBLE ARCH

| SIZE | LENGTH | PRESSURE RATING | MOVEMENT |

|---|---|---|---|

| DN600-24″ | 450mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +50/-76 mm, Lateral +/- 50 mm, Angular +/- 8.8º |

| DN700-28″ | 450mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +50/-76 mm, Lateral +/- 50 mm, Angular +/- 8º |

| DN800-32″ | 450mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +50/-76 mm, Lateral +/- 50 mm, Angular +/- 9.8º |

| DN900-36″ | 450mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +50/-76 mm, Lateral +/- 50 mm, Angular +/- 6.8º |

| DN1000-40″ | 450mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 6.2º |

| DN1050-42″ | 450mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 6º |

| DN1100-44″ | 450mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 5.8º |

| DN1150-46″ | 450mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 5.2º |

| DN1200-48″ | 450mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 5º |

| DN1250-50″ | 450mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 5º |

| DN1300-52″ | 500mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 4.8º |

| DN1350-54″ | 500mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 4.6º |

| DN1400-56″ | 500mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 4.4º |

| DN1450-58″ | 500mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 4.2º |

| DN1500-60″ | 500mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 4.2º |

| DN1600-64″ | 500mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 4º |

| DN1650-66″ | 500mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 3.8º |

| DN1700-68″ | 500mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 3.8º |

| DN1800-72″ | 500mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 3.6º |

| DN1900-76″ | 500mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 3º |

| DN1950-78″ | 500mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 3º |

| DN2000-80″ | 500mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 3º |

| DN2100-84″ | 500mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 2.8º |

| DN2200-88″ | 500mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 2.8º |

| DN2250-90″ | 500mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 2.8º |

| DN2300-92″ | 500mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 2.6º |

| DN2400-96″ | 500mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 2.6º |

| DN2500-100″ | 500mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 2.4º |

| DN2550-102″ | 500mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 2.4º |

| DN2600-104″ | 500mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 2.4º |

| DN2700-108″ | 500mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 2.4º |

| DN2800-112″ | 500mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 2.2º |

| DN2850-114″ | 500mm | 4 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 2.2º |

| DN2900-116″ | 500mm | 4 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 2.2º |

| DN3000-120″ | 500mm | 4 Barg (higher available) @ -40 to +140 ºC | Axial +70/-110 mm, Lateral +/- 70 mm, Angular +/- 2º |

SAFETECH. RUBBER BELLOWS MANUFACTURING – TRIPLE ARCH

| SIZE | LENGTH | PRESSURE RATING | MOVEMENT |

|---|---|---|---|

| DN600-24″ | 600mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +75/-114 mm, Lateral +/- 75 mm, Angular +/- 13.2º |

| DN700-28″ | 600mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +75/-114 mm, Lateral +/- 75 mm, Angular +/- 12º |

| DN800-32″ | 600mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +75/-114 mm, Lateral +/- 75 mm, Angular +/- 14.7º |

| DN900-36″ | 600mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +75/-114 mm, Lateral +/- 75 mm, Angular +/- 10.2º |

| DN1000-40″ | 600mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 9.3º |

| DN1050-42″ | 600mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 9º |

| DN1100-44″ | 600mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 8.7º |

| DN1150-46″ | 600mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 7.8º |

| DN1200-48″ | 600mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 7.5º |

| DN1250-50″ | 600mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 7.5º |

| DN1300-52″ | 650mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 7.2º |

| DN1350-54″ | 650mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 6.9º |

| DN1400-56″ | 650mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 6.6º |

| DN1450-58″ | 650mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 6.3º |

| DN1500-60″ | 650mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 6.3º |

| DN1600-64″ | 650mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 6º |

| DN1650-66″ | 650mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 5.7º |

| DN1700-68″ | 650mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 5.7º |

| DN1800-72″ | 650mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 5.4º |

| DN1900-76″ | 650mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 4.5º |

| DN1950-78″ | 650mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 4.5º |

| DN2000-80″ | 650mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 4.5º |

| DN2100-84″ | 650mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 4.2º |

| DN2200-88″ | 650mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 4.2º |

| DN2250-90″ | 650mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 4.2º |

| DN2300-92″ | 650mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 3.9º |

| DN2400-96″ | 650mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 3.9º |

| DN2500-100″ | 650mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 3.6º |

| DN2550-102″ | 650mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 3.6º |

| DN2600-104″ | 650mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 3.6º |

| DN2700-108″ | 650mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 3.6º |

| DN2800-112″ | 650mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 3.3º |

| DN2850-114″ | 650mm | 4 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 3.3º |

| DN2900-116″ | 650mm | 4 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 3.3º |

| DN3000-120″ | 650mm | 4 Barg (higher available) @ -40 to +140 ºC | Axial +105/-165 mm, Lateral +/- 105 mm, Angular +/- 3º |

SAFETECH. RUBBER BELLOWS MANUFACTURING – QUAD ARCH

| SIZE | LENGTH | PRESSURE RATING | MOVEMENT |

|---|---|---|---|

| DN600-24″ | 750mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +100/-152 mm, Lateral +/- 100 mm, Angular +/- 17.6º |

| DN700-28″ | 750mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +100/-152 mm, Lateral +/- 100 mm, Angular +/- 16º |

| DN800-32″ | 750mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +100/-152 mm, Lateral +/- 100 mm, Angular +/- 19.6º |

| DN900-36″ | 750mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +100/-152 mm, Lateral +/- 100 mm, Angular +/- 13.6º |

| DN1000-40″ | 750mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 12.4º |

| DN1050-42″ | 750mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 12º |

| DN1100-44″ | 750mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 11.6º |

| DN1150-46″ | 750mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 10.4º |

| DN1200-48″ | 750mm | 10 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 10º |

| DN1250-50″ | 750mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 10º |

| DN1300-52″ | 800mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 9.6º |

| DN1350-54″ | 800mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 9.2º |

| DN1400-56″ | 800mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 8.8º |

| DN1450-58″ | 800mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 8.4º |

| DN1500-60″ | 800mm | 8 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 8.4º |

| DN1600-64″ | 800mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 8º |

| DN1650-66″ | 800mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 7.6º |

| DN1700-68″ | 800mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 7.6º |

| DN1800-72″ | 800mm | 7 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 7.2º |

| DN1900-76″ | 800mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 6º |

| DN1950-78″ | 800mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 6º |

| DN2000-80″ | 800mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 6º |

| DN2100-84″ | 800mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 5.6º |

| DN2200-88″ | 800mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 5.6º |

| DN2250-90″ | 800mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 5.6º |

| DN2300-92″ | 800mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 5.2º |

| DN2400-96″ | 800mm | 6 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 5.2º |

| DN2500-100″ | 800mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 4.8º |

| DN2550-102″ | 800mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 4.8º |

| DN2600-104″ | 800mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 4.8º |

| DN2700-108″ | 800mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 4.8º |

| DN2800-112″ | 800mm | 5 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 4.4º |

| DN2850-114″ | 800mm | 4 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 4.4º |

| DN2900-116″ | 800mm | 4 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 4.4º |

| DN3000-120″ | 800mm | 4 Barg (higher available) @ -40 to +140 ºC | Axial +140/-220 mm, Lateral +/- 140 mm, Angular +/- 4º |

How to Select a Large Rubber Bellows

Temperature is the most critical as it directly influences the choice of rubber – but also the actual pressure capability of the bellows. The stated maximum rated pressure is maintained up to around 50ºC for most rubber bellows, for higher temperatures check the data in the Range tab.

Temperature is the most critical as it directly influences the choice of rubber – but also the actual pressure capability of the bellows. The stated maximum rated pressure is maintained up to around 50ºC for most rubber bellows, for higher temperatures check the data in the Range tab. The rubber compound used for the inner layer of the bellows must be compatible with the working fluid. Drinking water requires a WRAS approved EPDM, oils require Nitrile and so on – our Bellows Finder can help you with finding the right rubber.

The rubber compound used for the inner layer of the bellows must be compatible with the working fluid. Drinking water requires a WRAS approved EPDM, oils require Nitrile and so on – our Bellows Finder can help you with finding the right rubber. Moulded bellows are manufactured in set combinations of diameters and lengths. However, our handmade Safetech range can be manufactured in any diameter and length to suit your application, only the more standard sizes are shown on the Safetech range tab.

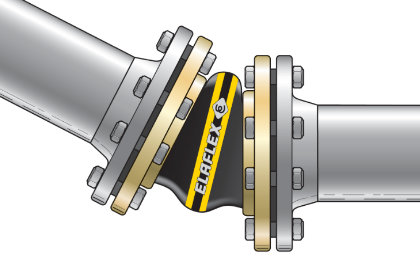

Moulded bellows are manufactured in set combinations of diameters and lengths. However, our handmade Safetech range can be manufactured in any diameter and length to suit your application, only the more standard sizes are shown on the Safetech range tab. Any flange drilling can be supplied; if you are uncertain about what you already have installed our Flange Finder will help you identify it. The HVAC and Elaflex ranges have swivel flanges; the Safetech range has full face rubber flanges. Our web shop stock is PN10/16. Bellows will exert a pressure force on the pipe (see FAQ) which must be restrained or absorbed at the piping anchors. All our flanged rubber expansion joints are available with tie rods and we can offer hinges or gimbals on the Elaflex and Safetech products.

Any flange drilling can be supplied; if you are uncertain about what you already have installed our Flange Finder will help you identify it. The HVAC and Elaflex ranges have swivel flanges; the Safetech range has full face rubber flanges. Our web shop stock is PN10/16. Bellows will exert a pressure force on the pipe (see FAQ) which must be restrained or absorbed at the piping anchors. All our flanged rubber expansion joints are available with tie rods and we can offer hinges or gimbals on the Elaflex and Safetech products. Moulded rubber bellows have a defined movement range, which is shown for each type in the Range tab, movements listed are non-concurrent (see FAQ). A Safetech bellows will be designed to meet your required movements.

Moulded rubber bellows have a defined movement range, which is shown for each type in the Range tab, movements listed are non-concurrent (see FAQ). A Safetech bellows will be designed to meet your required movements. Call our expert team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.

Call our expert team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.Safetech Rubber Bellow Expansion Joints:

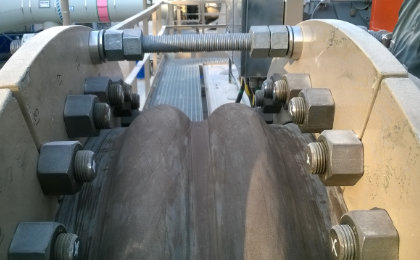

Safetech typically offers 1, 2, 3 or 4 convolutions in each diameter of expansion joint. All manufactured rubber bellows are available with a huge range of flange, material and restraint options:

Multiple arch engineered bellows

DN100 to DN3600+

MULTIPLE ARCH ENGINEERED RUBBER BELLOWS

Single, double, triple or quad arch

Each additional arch in the bellows provides additional movement capability. This allows very large axial, lateral or angular movements to be delivered by a single, compact expansion joint.

The length of the expansion joint can be adjusted to suit your piping layout or existing equipment meaning the full movement capacity of the bellows is available to you in all cases.

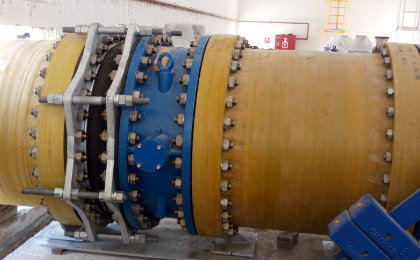

Pressure Balanced engineered bellows

DN100 to DN3000+

PRESSURE BALANCED ENGINEERED RUBBER BELLOWS

Eliminates Pressure Force

A pressure balanced rubber expansion joint uses two rubber bellows to provide the movement specified and a third, larger diameter rubber bellows to generate an equal pressure force. The larger diameter “balance” bellows is cross connected to the inlet and outlet flanges so it cancels out the pressure force of the smaller bellows. Net result no pressure force acting on your pipe, flanges or equipment.

Safetech can design and manufacture exactly what you need for your specific application so don’t be constrained by catalogue dimensions or performance. We can offer reducing bellows to connect between different pipe sizes, extended lengths to eliminate additional pipe, simple spool type ends for banding, non circular…

Restraint Hardware

Tie Rods, Lugs, Hinges, Collars

RESTRAINT HARDWARE

TIE RODS, LUGS, HINGES, COLLARS

Safetech’s preferred design is to manufacture the flange backing ring in segments with integral tie rod lugs. This approach makes assembly more straight forward as each segment is lighter to handle. Having the tie rod lug integral with the backing flange reduces bending stresses and eliminates bolt on lugs altogether, again an installation advantage. Safetech can also supply one piece flanges if requested. If the joint is to be used to allow easy dismantling of line equipment we can also provide a dismantling collar on the bellows which allows the tie rods to compress the convolutions(s) to ease removal.

Linings and Liners

PTFE, Stainless Steel

LININGS AND LINERS

PTFE, STAINLESS STEEL

Safetech can provide a PTFE lining in any of its rubber bellows, the PTFE affording greater chemical resistance than the rubber. We also provide a variety of Stainless Steel “Top Hat” liners which keep the flow away from the rubber convolutions – flow straightening vanes are an option. A metal liner is a good addition for any dirty media with solid content or elevated temperatures.

Can't see what you want? Need help?

Call us. Or use Live Chat.

For instant advice. We can custom-design and engineer almost any expansion joint you need for delivery in the UK or worldwide. Call our expert team on +44 (0) 1384 881188 Or email us sales@flexej.co.uk

Frequently Asked Questions

A. Our Flange Finder contains details for many common flanges. Typically, to be able to make the identification you need to know the bore size or outside diameter and number of bolts. For technical assistance contact us or use our Live Chat facility.

A. Yes, FlexEJ has full design capability for engineered metal expansion joints and can work to any recognised standard – typically EJMA, B31.3/Appendix X, EN14917 plus PED and/or other customer specifications. Engineered rubber expansion joints are typically designed to meet the FSA guidelines plus PED and/or other customer specifications For technical assistance please contact us or use the Live Help link on this page.

A. Yes, if you have the details we can normally offer an equivalent, our FAQ here gives the information we will need for a full selection. For technical assistance please contact us or use the Live Chat link on this page.

A. To identify an existing expansion joint we need to know: nominal bore, overall length and flange type plus service, temperature, pressure and required movement if known. Try our Flange Finder to help identify the flange and you can send us a picture of the existing part using the Contact us form. For technical assistance please contact us or use the LIVE CHAT link on this page.

A. Yes, our Elaflex ERV-R and ERP rubber bellows have WRAS, DVGW and ACS approval for drinking water, see our Elaflex pages for more information. The Safetech manufactured to order rubber bellows can be supplied with WRAS approved EPDM linings. Our MRCA copper ended metal expansion joints also have WRAS approval. For technical assistance please contact us or use the LIVE CHAT link on this page.

Please visit our full FAQ page to see all our frequently asked questions.