UNVENTED COMMERCIAL DHW SYSTEM VALVES

FlexEJ’s range of high-grade, commercial DHW system valves for FlexEJ’s PhexPak & Commercial buffer systems.

24hr Shipping

On all stock items ordered.

Mon-Thur by 2pm, 10am Fridays

Design & Manufacturing

Full in-house design & manufacture to EN / ASME / PED.

ISO14001 Accreditation

FlexEJ has an accredited Environmental Management System.

Commercial DHW System Valves

PRODUCT GUIDES

SYSTEM VALVEs

WHAT ARE UNVENTED SYSTEM VALVES?

ENABLES SAFE OPERATION AND CONTROL OF unvented DHW systems

TEMPERATURE & PRESSURE

Temperature and Pressure relief valves – protect against over pressure and/or temperature.

ANTI VACUUM

Anti Vacuum valves – protect against the buffer vessel being subjected to a high vacuum.

AUTO AIR VENTILATION

Auto Air Vents – ensure any air in the system is safely vented.

BALANCED SYSTEMS

Pressure and Balancing Valves – allow each feed from the DHW system to be controlled.

How to Apply DHW System Valves

The TPRV and PRV are both rated for the DHW heating power. This is a convenient way of expressing the capability of the valve based on one of the key parameters of the system design. Ratings include a 10% overpressure.

The TPRV and PRV are both rated for the DHW heating power. This is a convenient way of expressing the capability of the valve based on one of the key parameters of the system design. Ratings include a 10% overpressure. The system pressure has a direct bearing on the valve selection – the higher the pressure the greater the flow though the TPRV and PRV. The kW rating of each valve thus increase with system pressure.

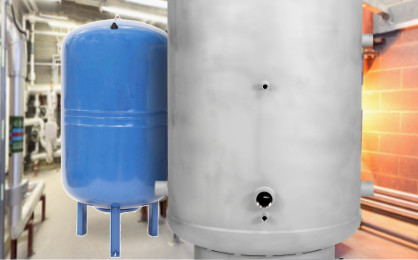

The system pressure has a direct bearing on the valve selection – the higher the pressure the greater the flow though the TPRV and PRV. The kW rating of each valve thus increase with system pressure. The system volume is used to select the Expansion Vessel. In a closed hot water circuit, the water cannot be compressed so any increase in volume, created by an increase in temperature, has to be accommodated by an expansion vessel. The vessel is rated for around 10% of the DHW system volume.

The system volume is used to select the Expansion Vessel. In a closed hot water circuit, the water cannot be compressed so any increase in volume, created by an increase in temperature, has to be accommodated by an expansion vessel. The vessel is rated for around 10% of the DHW system volume. Buffer vessels are designed for internal pressure but can be crushed by atmospheric pressure on the outside of the vessel if a vacuum is allowed to develop inside. The Anti Vacuum valve prevents this situation by admitting air into the system if vacuum develops.

Buffer vessels are designed for internal pressure but can be crushed by atmospheric pressure on the outside of the vessel if a vacuum is allowed to develop inside. The Anti Vacuum valve prevents this situation by admitting air into the system if vacuum develops. Entrained air in the system will tend to accumulate where the flow velocity is low at high points. The automatic vent valve releases this air.

Entrained air in the system will tend to accumulate where the flow velocity is low at high points. The automatic vent valve releases this air. Please call National Sales Manager Toby Stone on 07780 680870 or our specialist HVAC sales & support team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.

Please call National Sales Manager Toby Stone on 07780 680870 or our specialist HVAC sales & support team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.

DHW System Valves Range Overview

Temperature & Pressure Relief Valves

Protects against pressure and temperature limits being exceeded. Required for systems including unvented hot water storage – G3 requirements.

Applicable to :

- PhexStore

- Buffer Vessels

Selection Criteria :

- System design pressure (barg)

- Water Heating power (kW)

See product selector here

NOTE: All Temperature & Pressure Relief Valves are supplied with a set pressure of 4.7 barg, factory setting to other pressures with is available to order.

Pressure Relief Valves

Protects against over pressure. May be specified in conjunction with TPRV as additional protection.

Applicable to :

- PhexPak & PhexPak Lite

- PhexStore

- Buffer Vessels

Selection Criteria :

- System design pressure (barg)

See product selector here

NOTE: All Pressure Relief Valves are supplied with a set pressure of 4.7 barg, factory setting to other pressures with test is available to order.

Anti Vacuum Valves

Protects against a vacuum developing in the buffer or system in installations where there is a potential for the draw off flow rate to exceed the supply flow rate. This can occur in systems with multiple outlets below the level of the bottom of the buffer.

The valve admits air to the system if the vacuum set point is exceeded.Applicable to :

- PhexStore

- Buffer Vessels

Selection Criteria : None

Pressure Reducing Valves

Used to set a maximum pressure downstream of the valve. May be applied to individual service feeds that require maximum pressures set below the system design / PRV set point.

Applicable to :

- PhexPak & PhexPak Lite

- PhexStore

- Buffer Vessels

Selection Criteria :

- Downstream pressure (barg)

- Line Size (DN)

See product selector here

Automatic Air Vent Valves

Releases air which can collect at high points within the system. Shut off base allows easy AAV replacement.

Applicable to :

- PhexStore

- Buffer Vessels

Selection Criteria : None

Balancing Valves – Flow Setters

Balancing valves are required in heating water systems to help achieve the correct flow rate through the designated circuit in the system. Balancing valves, when regulated, force water from the most favoured to the least favoured circuits to achieve the design flow rate confirmed by measuring the actual flow rate.

Applicable to :

- PhexPak & PhexPak Lite

- PhexStore

- Buffer Vessels

Selection Criteria :

- Circuit design flow (l/min)

See product selector here

Potable Expansion Vessels

In a closed hot water circuit, the water cannot be compressed so any increase in volume, created by an increase in temperature, has to be accommodated by an expansion vessel.

When water is cold, the pre-charge pressure forces the bladder to collapse until the pump is started when the bladder starts to inflate. As the temperature in the system increases, with the associated increase in pressure and volume, the expanded water enters the bladder creating additional volume and lowering the pressure. When the temperature decreases, the pre-charge pressure forces the water from the bladder and back into the main water circuit.Applicable to :

- PhexPak & PhexPak Lite

- PhexStore

- Buffer Vessels

Selection Criteria :

- System Volume (l)

See product selector here

FlexEJ Commercial System Valve Finders

Please go ahead and try our Commercial DHW System Valve Finders and tables – but don’t hesitate to call our sales & support team on 01384 881188 if you need help or advice either on the valve selection of the whole commercial heating package configuration needed.

TPRV Valve Finder

Please search for Temperature & Pressure Relief Valves (TPRV) by pressure or power rating as required.

Please select…

PRESSURE RATING (barg)

POWER RATING (kW)

Barg

kW

BSP In

BSP Out

Shop Link

PRV Valve Finder

Please search for Pressure Relief Valves (PRV) by pressure or power rating as required.

Please select…

PRESSURE RATING (barg)

POWER RATING (kW)

Barg

kW

BSP In

BSP Out

Shop Link

NOTE: All Pressure Relief Valves are supplied with a set pressure of 4.7 barg, factory setting to other pressures with is available to order. Pressure is normally 1.1 x working pressure or 0.7 barg + working pressure, whichever is greatest. This prevents the valve chattering on its seat.

Pressure Reducing Valves

Please see the following Pressure Reducing Valves by Pressure Control Range (barg), Inlet and Outlet connection sizes (In/Out Size) – as well Max Inlet Pressure (max barg).

Barg

In Size

Out Size

Max Barg

Shop Link

| 1.0 - 6.0 | 1" BSP M | 1" BSP M | 25 | See in shop |

| 1.0 - 6.0 | 1.1/4" BSP M | 1.1/4" BSP M | 25 | See in shop |

| 1.0 - 6.0 | 1.1/2" BSP M | 1.1/2" BSP M | 25 | See in shop |

| 1.0 - 6.0 | 2" BSP M | 2" BSP M | 25 | See in shop |

| 0.5 - 6.0 | DN65 PN16 | DN65 PN16 | 16 | See in shop |

Balancing Valves

Please see the following Balancing Valves by Outlet Flow Control Range (Flow l/m), Inlet and Outlet connection sizes (In/Out Size) – as well Max Inlet Pressure (max barg).

Flow (l/m)

In Size

Out Size

Max Barg

Shop Link

| 5 -13 | 3/4" F | 3/4" F | 10 | See in shop |

| 7 - 28 | 3/4" F | 3/4" F | 10 | See in shop |

| 10 - 40 | 1" BSP F | 1" BSP F | 10 | See in shop |

| 20 - 70 | 1.1/4" BSP F | 1.1/4" BSP F | 10 | See in shop |

| 30 - 120 | 1.1/2" BSP F | 1.1/2" BSP F | 10 | See in shop |

| 50 - 200 | 2" BSP F | 2" BSP F | 10 | See in shop |

Potable Expansion Vessels

Please see the following Potable Expansion Vessels by System Volume (Vol l), Vessel Capacity (Cap l), Inlet Connection Size (In Size) and Design Pressure (barg).

Vol (l)

Cap (l)

In Size

Barg

Shop Link

| 250 | 25 | 3/4" M | 10 | See in shop |

| 600 | 60 | 1" BSP M | 10 | See in shop |

| 800 | 80 | 1" BSP M | 10 | See in shop |

| 1,000 | 100 | 1" BSP M | 10 | See in shop |

| 2,000 | 200 | 1.1/4" BSP M | 10 | See in shop |

| 3,000 | 300 | 1.1/4" BSP M | 10 | See in shop |

| 5,000 | 500 | 1.1/4" BSP M | 10 | See in shop |

| 8,000 | 800 | 1.1/2" BSP M | 10 | See in shop |

| 10,000 | 1,000 | 1.1/2" BSP M | 10 | See in shop |

Your Specific Requirements

We understand that there are many different challenges and obstacles to overcome when installing plant room equipment, whether that’s newbuild or refurb. With that sometimes comes a necessity to adapt to unusual scenarios. If you believe the standard range isn’t suitable for your needs, get in touch with our sales & support team and they can offer all the support you need.

Can't see what you want? Need help?

Call us. Or use Live Chat.

For instant advice. We can custom-design and engineer almost any expansion joint you need for delivery in the UK or worldwide. Call our expert team on +44 (0) 1384 881188 Or email us sales@flexej.co.uk

Frequently Asked Questions

A. A buffer vessel is a storage tank – in the case of a DHW system it stores hot water. This water is immediately available to the DHW consumers and eliminates any delay in the heat source coming on line or up to temperature.

A. That depends on the heat source you have and the demand on the DHW draw off. If the heat source is constantly available, always at the correct temperature and capable of supplying the peak demand of DHW then no, you don’t need a buffer vessel. In a practical system it would be expensive and inefficient to meet those criteria so a buffer vessel is normally included.

A. This depends on the capability and availability of the heat source and the peak demand of the DHW system. The correct buffer vessel volume allows an economic and energy efficient design to be achieved.

A. We would recommend using the FlexEJ PhexPak as it provides isolation and control in one convenient package.

A. The buffer vessels do not have specific approval number but are suitable for potable water and meets the needs of a Water Regulation 4 material approval due to being 100% 316 stainless steel.

A. Yes, all of our standard buffer vessels are supplied with an industry standard 2¼” boss to fit an immersion heater.

A. Yes, there is a 2½” connection on top to accommodate up to the largest size commercial TPRVs.

A. Yes we can. Do see our new DHW System Valves page for compatible valves or call our expert team for assistance with selection with this or anything in FlexEJ’s buffer vessels and PhexPak packaged plate heat exchanger ranges.