PRESSURE VESSEL DESIGN, MANUFACTURING AND OEM FABRICATION

From pressure & buffer vessel design to precision-engineered tanks, buffer vessels, skids, filters, strainers & silencers.

24hr Shipping

On all stock items ordered.

Mon-Thur by 2pm, 10am Fridays

Design & Manufacturing

Full in-house design & manufacture to EN / ASME / PED.

ISO14001 Accreditation

FlexEJ has an accredited Environmental Management System.

Pressure Vessel Design & Manufacturing

FlexEJ has a specialist fabrication team who design, engineer and manufacture pressure vessels at our UK fabrication plant. We specialise in custom pressure vessels with demanding expansion, pressure, technical and quality requirements and can manufacture vessels in a wide range of metals including Carbon Steel, Stainless Steel, chrome moly (CrMo) and Duplex:

Pressure Vessel Design & Manufacture

FlexEJ designs to the commonly required vessel codes including – ASME VIII (not U stamp), EN13445 and PD5500. We are PED accredited meeting the requirements of module(s) D1, E1 & H. Alternatively, we offer build-to-print where the code calculation has been completed by others and the design envelope already exists.

Pressure Vessel Design & Engineering

In-house capability

PRESSURE VESSEL DESIGN & ENGINEERING

In house capability

FlexEJ uses PV Elite suite for calculations which integrates with our Solid Works for design and detailing. Material traceability and NDT are both managed through a specially developed database which integrates with our business system for instant reporting and indexing/retrieval of certification ready for inclusion in the manufacturing data book.

We have long experience of working with OEMs to design and build the pressure boundary for specialist internals such as filters, strainers, de-misters, separators, heaters and silencers.

Alternatively, FlexEJ offers build-to-print where the code calculation has been completed by others and the design envelope exists or we can take concept drawings forward to full manufacturing designs.

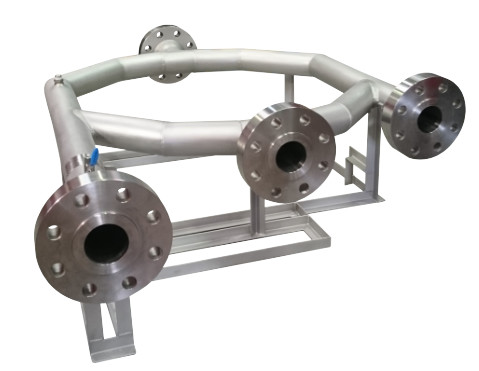

Filters, Strainers, Silencers, Flares.

Your manufacturing partner

FILTERS, STRAINERS, SILENCERS, FLARES.

Pressure Boundary for OEMs

FlexEJ is an experience manufacturing partner for OEMs requiring pressure boundary fabrication and final product assembly.

Filters, strainers, de-misters, separators, heaters, silencers, flare tips… the list is extensive.

We understand the requirements of OEMs and have developed long lasting partnerships with major manufacturers. From simple build to print through to complete pressure boundary design and the final product we will be pleased to work with you.

Pressure Vessel Manufacture

Complex, high specification welcome

PRESSURE VESSEL MANUFACTURE

Typically to 3m diameter

FlexEJ specialises in the manufacture of small to medium pressure vessels. Backed up by our team of engineers and support office staff, we are known for high quality work, with excellent manufacturing documentation.

Typical diameters up to 3,000mm

Typical weights up to 15,000Kg.

Typical lengths up to 12,000mm

Typical wall thicknesses from 1mm to 50mm

We regularly fabricate pressure vessels from a wide range of metals, for example:

Stainless Steel 316/L, 304/L

Carbon Steels A516, A105

Chrome Moly (CrMo)

Alloy 625, 825

All our welders are on site in our own factory in the UK.

Skids & Packages

Vessel Packaging

SKIDS & PACKAGES

Integration with your supply

FlexEJ offers complete vessel packages with skid, piping and your free issue items as required. We are highly experienced in meeting complex requirements for documentation, in process NDT and tests on projects.

We have provided vessel packages as a long term manufacturing partner to an OEM, whatever your needs please get in contact.

Can't see what you want? Need help?

Call us. Or use Live Chat.

For instant advice. We can custom-design and engineer almost any expansion joint you need for delivery in the UK or worldwide. Call our expert team on +44 (0) 1384 881188 Or email us sales@flexej.co.uk

Frequently Asked Questions

A. No, we only manufacture to order. For technical assistance please contact us or use our Live Chat facility.

A. Typically up to 3m diameter, 10m long, 15t weight. Please let us know your requirements and we can quickly advise if it is within our capability. There are some examples shown in our gallery – take a look by scrolling down to the bottom of the pressure vessels page. For technical assistance please contact us or use our Live Chat facility.

A. Yes, FlexEJ designs and manufactures engineered pressure vessels to PED, ASME 8, EN13445 and PD5500 as required – plus customer specifications. We can also manufacture to your design and drawing. For technical assistance contact us or use our Live Chat facility.

A. No, at present FlexEJ is not U Stamp accredited. For technical assistance please contact us or use our Live Chat facility.

A. A. PD5500 is a Specification for unfired, fusion welded pressure vessels. Formerly known as BS5500, it is a UK standard FlexEJ uses to design pressure vessels. For technical assistance contact us or use our Live Chat facility.

A. No, we only manufacture to order. For sales assistance please contact us or use our Live Chat facility.

A. To design a pressure vessel we need to know the design pressure, temperature, working fluid, volume (or length & diameter) and what material is required. The number and size of connections to the vessel has a big impact on both the design and cost so this is also useful early design information. For technical assistance please contact us or use the LIVE CHAT link on this page.