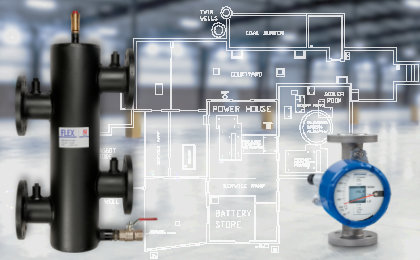

FlexEJ Low Loss Headers

FlexEJ’s high-quality low loss headers are designed and built in the UK by FlexEJ for optimal boiler room efficiency and direct value.

24hr Shipping

On all stock items ordered.

Mon-Thur by 2pm, 10am Fridays

Design & Manufacturing

Full in-house design & manufacture to EN / ASME / PED.

ISO14001 Accreditation

FlexEJ has an accredited Environmental Management System.

Low Loss Headers

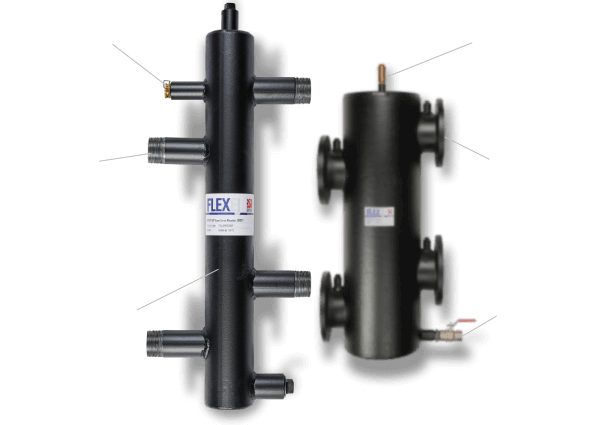

FlexEJ’s range of Low Loss Headers, also known as hydraulic separators, covers popular sizes from DN20/30kW up to DN150/1,480kW in our standard low loss header ranges with larger sizes and multiple circuit designs built to order:

PRODUCT GUIDES

LOW LOSS HEADERS

WHAT IS A LOW LOSS HEADER?

LOW LOSS HEADERS DECOUPLE THE BOILERS FROM THE SYSTEM..

Materials

Carbon steel with BSP threaded connections or PN flanges.

Application

Heating water services, boiler arrays.

Rating

HP Range – 10 Barg @ 110°C. LP Range – 6 Barg @ 110°C.

Web Shop

Available online with next day delivery from our web shop.

LP LOW LOSS HEADER

| SIZE | POWER | PRESSURE RATING | SPECIFICATION | IN SHOP |

|---|---|---|---|---|

| DN20-R¾″ | 30 kW | 6 Barg @ 110 ºC | Threaded BSP R, installation length nominally 110 mm, overall height 438 mm | Yes |

| DN25-R1″ | 50 kW | 6 Barg @ 110 ºC | Threaded BSP R, installation length nominally 135 mm, overall height 438 mm | Yes |

| DN32-R1¼” | 70 kW | 6 Barg @ 110 ºC | Threaded BSP R, installation length nominally 250 mm, overall height 614 mm | Yes |

| DN40-R1½” | 110 kW | 6 Barg @ 110 ºC | Threaded BSP R, installation length nominally 270 mm, overall height 614 mm | Yes |

| DN50-R2″ | 160 kW | 6 Barg @ 110 ºC | Threaded BSP R, installation length nominally 300 mm, overall height 614 mm | Yes |

| DN65-2½” | 280 kW | 6 Barg @ 110 ºC | Flanged PN6, installation length nominally 356 mm, overall height 634 mm | Yes |

HP LOW LOSS HEADER

| SIZE | POWER | PRESSURE RATING | SPECIFICATION | IN SHOP |

|---|---|---|---|---|

| DN50-2″ | 200 kW | 10 Barg @ 110 ºC | Flanged PN16, installation length nominally 320 mm, overall height 740 mm | Yes |

| DN65-2½” | 310 kW | 10 Barg @ 110 ºC | Flanged PN16, installation length nominally 355 mm, overall height 760 mm | Yes |

| DN80-3″ | 440 kW | 10 Barg @ 110 ºC | Flanged PN16, installation length nominally 380 mm, overall height 780 mm | Yes |

| DN100-4″ | 790 kW | 10 Barg @ 110 ºC | Flanged PN16, installation length nominally 380 mm, overall height 820 mm | Yes |

| DN125-5″ | 1,230 kW | 10 Barg @ 110 ºC | Flanged PN16, installation length nominally 430 mm, overall height 875 mm | Yes |

| DN150-6″ | 1,480 kW | 10 Barg @ 110 ºC | Flanged PN16, installation length nominally 430 mm, overall height 945 mm | Yes |

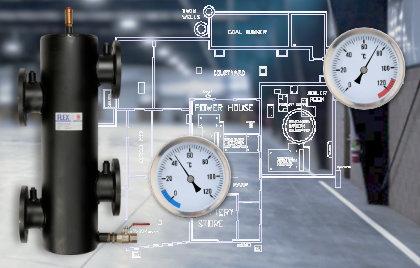

Low Loss Headers in HVAC Systems

If a system has more than one pump operating there is the possibility of the pumps interacting with one another which results in instability. To avoid this a hydraulic separator – a low loss header – is introduced into the system.

If a system has more than one pump operating there is the possibility of the pumps interacting with one another which results in instability. To avoid this a hydraulic separator – a low loss header – is introduced into the system. Not always, it depends on the system design and components. Low Loss Headers do introduce mixing of flow and return which results in temperature variations, this should be taken into consideration in the overall system design and control.

Not always, it depends on the system design and components. Low Loss Headers do introduce mixing of flow and return which results in temperature variations, this should be taken into consideration in the overall system design and control. A very common application of Low Loss Headers is with boiler cascades, the hydraulic separation decouples the boiler cascade from the system. This should allow, with proper system design, the boilers/boiler circuit flow to optimise at best efficiency for any system conditions.

A very common application of Low Loss Headers is with boiler cascades, the hydraulic separation decouples the boiler cascade from the system. This should allow, with proper system design, the boilers/boiler circuit flow to optimise at best efficiency for any system conditions. The flow rate and design flow velocity normally determine the size of the Low Loss Header body. Commonly the total boiler power and temperature difference are used as indicative of flow rate but secondary circuit flow rates may be higher and should be considered.

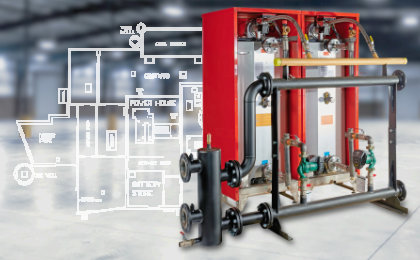

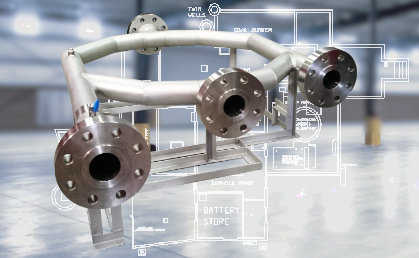

The flow rate and design flow velocity normally determine the size of the Low Loss Header body. Commonly the total boiler power and temperature difference are used as indicative of flow rate but secondary circuit flow rates may be higher and should be considered. FlexEJ can design and build to order large, multi-circuit low loss headers, manifolds, buffer vessels and piping spools. Please let us know what you need.

FlexEJ can design and build to order large, multi-circuit low loss headers, manifolds, buffer vessels and piping spools. Please let us know what you need. Call our HVAC specialists on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.

Call our HVAC specialists on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.FlexEJ’s Low Loss Headers

Robust and great value for money, FlexEJ’s HVAC Low Loss Headers — also known as Hydraulic Separators — are manufactured by us in the UK to our own design. DN20 to DN150 are standard stock and available on a 24hr despatch basis directly from our web shop. Other configurations are available. FlexEJ can also manufacture to meet specific client requirements, please get in touch.

Low Loss Header Applications

The hydraulic separation provided by a low loss header allows multiple pumped circuits to work independently from one another – which is particularly important in achieving the most efficient operation and control of condensing boilers and boiler cascades. The use of a low loss header is recommended to minimise interaction between primary circuits and the secondary circuits, the primary typically working at a constant flow rate and the secondary at varying flow rate and water temperature. For a full discussion of low loss header design please see our what is a low loss header page. The low flow velocity in the low loss header body promotes separation of air and dirt from the flow. FlexEJ provide a DN25 ball valve connection for dirt removal and a high quality automatic air vent valve with all HP low loss headers, the LP range have plugged connections and an optional valve kit.

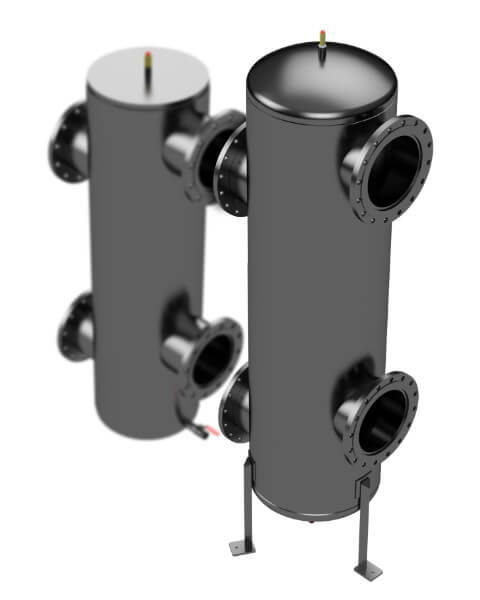

LP Low Loss Header Range

Designed for simpler, lower power systems these low loss headers have threaded connections from DN20 up to DN50 and PN6 flanges on the DN65. A single thermopocket is included on all sizes except DN20 and DN25. Vent and drain connections are supplied plugged, there is an optional valve kit.

LP Features

All our LP low loss headers have:- Rating of 6 Barg at 110°C

- Carbon steel body with BSP threaded connections except DN65 flanged PN6

- Optional valve kit of Flamco AAV and DN25 drain valve available from our web shop

- Optional 3 port horizontal headers (manifolds) available from our web shop

- Optional insulation jackets custom-designed for our LP range available in the web shop

- Single temperature probe port supplied with thermopocket and clip (except DN20 & DN25)

- DN20 to DN65 available from stock as standard

| Connection | Body Size (DN mm) | Flow Rate (m3/Hr) | Power (kW) | Code Buy Now |

|---|---|---|---|---|

| DN20-R¾″ | 40mm | 1.3 | 30kW | FEJLLH020BSP |

| DN25-R1″ | 50mm | 2.0 | 50kW | FEJLLH025BSP |

| DN32-R1¼″ | 65mm | 3.0 | 70kW | FEJLLH032BSP |

| DN40-R1½″ | 80mm | 4.7 | 110kW | FEJLLH040BSP |

| DN50-R2″ | 100mm | 6.9 | 160kW | FEJLLH050BSP |

| DN65-2½″ | 125mm | 12.0 | 280kW | FEJLLH065PN6 |

HP Low Loss Header Range

The high-power range is designed for larger, more complex commercial systems. All sizes flanged PN16 with temperature probe ports on all connections as standard. Supplied with Flamco AAV and DN25 drain ball valve.

HP Features

All our HP low loss headers have:- Rating of 10 Barg at 110°C

- Carbon steel body with PN16 flanges

- Flamco AAV with integral shut off valve

- DN25 drain valve

- Temperature probe ports on all connections

- Optional insulation jackets custom-designed for our HP range also available in the web shop

- DN50 to DN150 available from stock as standard

- Custom sizes, multiple connection adaptors and specifications

| Connection | Body Size (DN mm) | Flow Rate (m3/Hr) | Power (kW) | Code Buy Now |

|---|---|---|---|---|

| DN50-2″ | 100mm | 8.6 | 200kW | FEJLLH050 |

| DN65-2½″ | 125mm | 13.3 | 310kW | FEJLLH065 |

| DN80-3″ | 150mm | 18.9 | 440kW | FEJLLH080 |

| DN100-4″ | 200mm | 34.0 | 790kW | FEJLLH100 |

| DN125-5″ | 250mm | 52.9 | 1,230kW | FEJLLH125 |

| DN150-6″ | 250mm | 63.6 | 1,480kW | FEJLLH150 |

Stock Low Loss Header Finder

Do try our online low loss header product finder (below) to check if we have a low loss header (hydraulic separator) size and rating that meets your immediate needs – with 24hr shipping. If not then do call us on the usual 01384 881188 or use LIVE CHAT or drop a note or specification to us via our Get A Quote page. We can also help with technicalities, drawings and whatever you need and even our custom/any size low loss headers can be produced with a surprisingly quick turnaround (typically 10-14 days). We also have a handy Flange Finder if you simply need to identify flange connections needed.

Stock Low Loss Header Finder

Search for FlexEJ low loss headers by connection (pipe) size and/or by Boiler Rating or Heat Pump Rating as required:

Custom-Manufactured HP Low Loss Headers

FlexEJ’s custom-manufactured high-power range is designed for even larger, more complex commercial systems and can also be fully engineered to fully comply with project requirements. The base designs have PN16 flange connections and are normally supplied with Flamco AAV and a DN25 drain ball valve – typically built to order within 14 days (subject to exact specification). Full documentation and drawing package available.

Custom HP Features

Our custom HP low loss headers have:- Carbon steel body with PN16 flanges

- Flamco AAV with integral shut off valve

- DN25 drain valve

- Fully configurable design

- DN150 to DN600 available to order with 14 days lead time (typical)

- Multiple additional connections as required

Horizontal Headers (Manifolds)

Insulation Jackets

Silicone coated 530 g/m2 e-glass cloth inner and outer, black. Mineral rock fibre blanket filler 0.040 W/mk. Velcro hook and loop flaps plus draw cords.

Reduces heat loss by 90% in typical conditions.

Low Loss Header Calculation and Sizing

Power Rating and Flow Rate

The power rating quoted is a nominal value based on an assumed flow rate; the low loss header will perform above or below this figure. The tables above show performance for the FlexEJ Low Loss Headers with a 20°C temperature difference at flow rates typical for the connection sizes. Please contact us for further application assistance. All FlexEJ standard HP LLH are rated at 10 Barg at 110°C, standard LP LLH are rated at 6 Barg at 110°C, all calculated to PD5500 Category 3 and are SEP category under the PED.

Low Loss Header Design and Build

Custom built or delivered in 24hrs?

You are very welcome to call to talk through your requirements or any technicalities that are concerning you — on +44 (0) 1384 881188 — or please use the Get A Quote form below or order direct at UK factory prices from our low loss header shop pages with 24hr shipping as standard on all stock items.

Can't see what you want? Need help?

Call us. Or use Live Chat.

For instant advice. We can custom-design and engineer almost any expansion joint you need for delivery in the UK or worldwide. Call our expert team on +44 (0) 1384 881188 Or email us sales@flexej.co.uk

Frequently Asked Questions

A. Yes, to some extent, as the flow velocity in the body is low. We provide a Flamco AAV and DN25 drain valve on all FlexEJ low loss headers. However, separation is not as efficient as using a dedicated air/dirt separator as the main low velocity section in the LLH is bounded by turbulent cross flows.

A. Opinions vary but ideally all the primary circuit and secondary circuit flow and returns should be brought together in horizontal manifolds before connection to the low loss header.

A. On a vertical low loss header the returns connect at the bottom and the flows at the top. If the connections are staggered side to side then the lower pair are normally the primary side.

A. Sizing can be expressed in terms of flow rate or power. In heating systems, the total boiler power in the primary circuit is often taken as the sizing criteria. The power rating is directly proportional to the flow rate and temperature difference as given by m.Cp.Δt – Power (kW) = Mass flow rate (kg/s) * Specific Heat of Water (kJ/kg°K) * Temperature difference (°K). Our product table above shows both nominal flow rate and power ratings.

A. We have an online low loss header calculator we’ve built to help you – or do please get in touch with the details of your system and we will be pleased to help.

A. Based on the flow rate through the low loss header the body is sized to achieve a very low flow velocity – typically less than 0.3m/s. This low velocity ensures a low pressure drop between flow and return.

A. Yes – strictly speaking hydraulic separation between circuits is achieved using a low loss header.

A. A low loss header (LLH) provides hydraulic separation between multiple pumped circuits. This allows each circuit to operate independently and to be controlled for optimum efficiency. The header presents very low pressure drop bypass between the flow and return. FlexEJ low loss headers are provided with sensor ports on all four branches so whatever control system is being implemented you will have the port you need.