HIGH-QUALITY, FLEXIBLE METAL HOSE ASSEMBLIES AND END-FITTINGS

FlexEJ designs and manufactures fully-engineered, braided metal hose assemblies from DN6 to DN200 with custom end-fittings.

24hr Shipping

On all stock items ordered.

Mon-Thur by 2pm, 10am Fridays

Design & Manufacturing

Full in-house design & manufacture to EN / ASME / PED.

ISO14001 Accreditation

FlexEJ has an accredited Environmental Management System.

Metal Hose Assemblies

FlexEJ designs and manufactures fully-engineered flexible metal hose assemblies in diameters from DN6 to DN200. Hose core materials available include 321 stainless steel, 316 stainless steel and alloy 625:

PRODUCT GUIDES

METAL HOSE

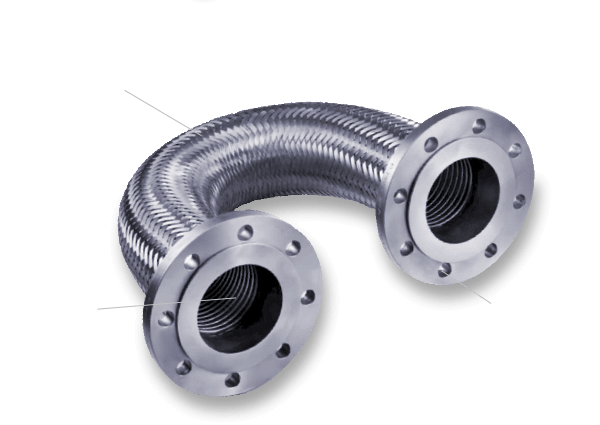

WHAT IS A METAL HOSE ASSEMBLY?

A CORE OF CONVOLUTED METAL HOSE, BRAID AND END FITTINGS..

Design

Extensive range of core hose and materials suitable for a wide range of industrial services.

Performance

High quality EN10380 hose in 321 or 316 stainless steel up to 625 Nickel alloy.

Application

FlexEJ will help you select the right hose for the application.

Configurable

Flanges or a vast selection of other end fittings, materials, lengths can all be specified to order.

METAL HOSE WITH NO EXTERNAL BRAID

| SIZE | LENGTH | RATING | MOVEMENTS | IN SHOP |

|---|---|---|---|---|

| DN6-¼” | Any | 10 Barg @ 20 ºC to 5 Barg @ 500 ºC | Static bend radius 16 mm, dynamic bend radius 110 mm | |

| DN10-⅜” | Any | 5.5 Barg @ 20 ºC to 2.75 Barg @ 500 ºC | Static bend radius 22 mm, dynamic bend radius 150 mm | |

| DN12-½” | Any | 5.5 Barg @ 20 ºC to 2.75 Barg @ 500 ºC | Static bend radius 24 mm, dynamic bend radius 165 mm | |

| DN16-⅝” | Any | 5 Barg @ 20 ºC to 2.5 Barg @ 500 ºC | Static bend radius 28 mm, dynamic bend radius 195 mm | |

| DN20-¾” | Any | 4.1 Barg @ 20 ºC to 2.05 Barg @ 500 ºC | Static bend radius 30 mm, dynamic bend radius 200 mm | |

| DN25-1″ | Any | 4.1 Barg @ 20 ºC to 2.05 Barg @ 500 ºC | Static bend radius 44 mm, dynamic bend radius 200 mm | |

| DN32-1¼” | Any | 3.4 Barg @ 20 ºC to 1.7 Barg @ 500 ºC | Static bend radius 55 mm, dynamic bend radius 250 mm | |

| DN40-1½” | Any | 2.4 Barg @ 20 ºC to 1.2 Barg @ 500 ºC | Static bend radius 70 mm, dynamic bend radius 250 mm | |

| DN50-2″ | Any | 1 Barg @ 20 ºC to 0.5 Barg @ 500 ºC | Static bend radius 90 mm, dynamic bend radius 350 mm | |

| DN65-2½” | Any | 1 Barg @ 20 ºC to 0.5 Barg @ 500 ºC | Static bend radius 110 mm, dynamic bend radius 410 mm | |

| DN80-3″ | Any | 1 Barg @ 20 ºC to 0.5 Barg @ 500 ºC | Static bend radius 130 mm, dynamic bend radius 450 mm | |

| DN100-4″ | Any | 0.1 Barg @ 20 ºC to 0.05 Barg @ 500 ºC | Static bend radius 131 mm, dynamic bend radius 530 mm | |

| DN125-5″ | Any | 0.1 Barg @ 20 ºC to 0.05 Barg @ 500 ºC | Static bend radius 189 mm, dynamic bend radius 800 mm | |

| DN150-6″ | Any | 0.1 Barg @ 20 ºC to 0.05 Barg @ 500 ºC | Static bend radius 216 mm, dynamic bend radius 1050 mm | |

| DN200-8″ | Any | 0.1 Barg @ 20 ºC to 0.05 Barg @ 500 ºC | Static bend radius 281 mm, dynamic bend radius 1300 mm | |

METAL HOSE WITH ONE EXTERNAL BRAID

| SIZE | LENGTH | RATING | MOVEMENTS | IN SHOP |

|---|---|---|---|---|

| DN6-¼” | Any | 167 Barg @ 20 ºC to 83.5 Barg @ 500 ºC | Static bend radius 25 mm, dynamic bend radius 110 mm | |

| DN10-⅜” | Any | 100 Barg @ 20 ºC to 50 Barg @ 500 ºC | Static bend radius 38 mm, dynamic bend radius 150 mm | |

| DN12-½” | Any | 74 Barg @ 20 ºC to 37 Barg @ 500 ºC | Static bend radius 45 mm, dynamic bend radius 165 mm | |

| DN16-⅝” | Any | 70 Barg @ 20 ºC to 35 Barg @ 500 ºC | Static bend radius 50 mm, dynamic bend radius 195 mm | |

| DN20-¾” | Any | 65 Barg @ 20 ºC to 32.5 Barg @ 500 ºC | Static bend radius 70 mm, dynamic bend radius 200 mm | |

| DN25-1″ | Any | 50 Barg @ 20 ºC to 25 Barg @ 500 ºC | Static bend radius 85 mm, dynamic bend radius 200 mm | |

| DN32-1¼” | Any | 39 Barg @ 20 ºC to 19.5 Barg @ 500 ºC | Static bend radius 105 mm, dynamic bend radius 250 mm | |

| DN40-1½” | Any | 35 Barg @ 20 ºC to 17.5 Barg @ 500 ºC | Static bend radius 127 mm, dynamic bend radius 250 mm | |

| DN50-2″ | Any | 30 Barg @ 20 ºC to 15 Barg @ 500 ºC | Static bend radius 160 mm, dynamic bend radius 350 mm | |

| DN65-2½” | Any | 26 Barg @ 20 ºC to 13 Barg @ 500 ºC | Static bend radius 200 mm, dynamic bend radius 410 mm | |

| DN80-3″ | Any | 22 Barg @ 20 ºC to 11 Barg @ 500 ºC | Static bend radius 230 mm, dynamic bend radius 450 mm | |

| DN100-4″ | Any | 20 Barg @ 20 ºC to 10 Barg @ 500 ºC | Static bend radius 218 mm, dynamic bend radius 530 mm | |

| DN125-5″ | Any | 20 Barg @ 20 ºC to 10 Barg @ 500 ºC | Static bend radius 315 mm, dynamic bend radius 800 mm | |

| DN150-6″ | Any | 23 Barg @ 20 ºC to 11.5 Barg @ 500 ºC | Static bend radius 360 mm, dynamic bend radius 1050 mm | |

| DN200-8″ | Any | 15 Barg @ 20 ºC to 7.5 Barg @ 500 ºC | Static bend radius 468 mm, dynamic bend radius 1300 mm | |

METAL HOSE WITH TWO EXTERNAL BRAIDS

| SIZE | LENGTH | RATING | MOVEMENTS | IN SHOP |

|---|---|---|---|---|

| DN6-¼” | Any | 220 Barg @ 20 ºC to 110 Barg @ 500 ºC | Static bend radius 25 mm, dynamic bend radius 110 mm | |

| DN10-⅜” | Any | 178 Barg @ 20 ºC to 89 Barg @ 500 ºC | Static bend radius 38 mm, dynamic bend radius 150 mm | |

| DN12-½” | Any | 103 Barg @ 20 ºC to 51.5 Barg @ 500 ºC | Static bend radius 45 mm, dynamic bend radius 165 mm | |

| DN16-⅝” | Any | 125 Barg @ 20 ºC to 62.5 Barg @ 500 ºC | Static bend radius 50 mm, dynamic bend radius 195 mm | |

| DN20-¾” | Any | 86 Barg @ 20 ºC to 43 Barg @ 500 ºC | Static bend radius 70 mm, dynamic bend radius 200 mm | |

| DN25-1″ | Any | 76 Barg @ 20 ºC to 38 Barg @ 500 ºC | Static bend radius 85 mm, dynamic bend radius 200 mm | |

| DN32-1¼” | Any | 57 Barg @ 20 ºC to 28.5 Barg @ 500 ºC | Static bend radius 105 mm, dynamic bend radius 250 mm | |

| DN40-1½” | Any | 55 Barg @ 20 ºC to 27.5 Barg @ 500 ºC | Static bend radius 127 mm, dynamic bend radius 250 mm | |

| DN50-2″ | Any | 44 Barg @ 20 ºC to 22 Barg @ 500 ºC | Static bend radius 160 mm, dynamic bend radius 350 mm | |

| DN65-2½” | Any | 46 Barg @ 20 ºC to 23 Barg @ 500 ºC | Static bend radius 200 mm, dynamic bend radius 410 mm | |

| DN80-3″ | Any | 40 Barg @ 20 ºC to 20 Barg @ 500 ºC | Static bend radius 230 mm, dynamic bend radius 450 mm | No |

How to specify a metal expansion joint

We design and manufacture flexible metal hose assemblies to meet your exact and sometimes quite demanding requirements.

We design and manufacture flexible metal hose assemblies to meet your exact and sometimes quite demanding requirements. Metal hose is designed to work by angulation only, it should not be used for axial movement. For this reason S shaped or U shaped installations are common, generally the hose should be perpendicular to the direction of movement.

Metal hose is designed to work by angulation only, it should not be used for axial movement. For this reason S shaped or U shaped installations are common, generally the hose should be perpendicular to the direction of movement. Metal hose can be applied at very high pressures with multiple external braids. Increasing temperature will reduce the pressure capability of the hose.

Metal hose can be applied at very high pressures with multiple external braids. Increasing temperature will reduce the pressure capability of the hose. The most common material used for metal hose is Stainless Steel – 304, 321, 316 – and for more demanding applications Nickel Alloys – 625, 800, 825. Corrosion is the most likely failure mode for the hose itself so the correct material selection is important.

The most common material used for metal hose is Stainless Steel – 304, 321, 316 – and for more demanding applications Nickel Alloys – 625, 800, 825. Corrosion is the most likely failure mode for the hose itself so the correct material selection is important. Assemblies with lengths to 50m in smaller diameters and hose diameters to DN200 can be manufactured. There is a huge choice of fittings for metal hose assemblies, just let us know what you require. It is essential that no torsion is applied to the hose when installed so one fixed and one swivel end is common.

Assemblies with lengths to 50m in smaller diameters and hose diameters to DN200 can be manufactured. There is a huge choice of fittings for metal hose assemblies, just let us know what you require. It is essential that no torsion is applied to the hose when installed so one fixed and one swivel end is common. Call our expert team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.

Call our expert team on +44 (0) 1384 881188 or email us at sales@flexej.co.uk or use Live Chat on this web site – we are here to help, please get in touch.Metal Hose Assemblies

A metal hose assembly typically consists of a convoluted metal hose core, external braiding if required and end fittings:

Hose Core

DN60 to DN200+

HOSE CORE

Stainless Steels, Nickel Alloys

The hose core is manufactured from a strip of material that is formed and continuously welded into a thin tube which is simultaneously convoluted to form a hose. The core is robust but will extend on the application of internal pressure so an external braid is applied which restrains the pressure force and keeps the hose at a set length.

External Braids & Spirals

DN6 to DN200+

EXTERNAL BRAIDS AND SPIRALS

Eliminate Pressure Force

The external braid is not added to the hose for mechanical protection. It is a key component and considerably increases the pressure rating of the hose assembly by restraining the pressure force. Single braid is the most common but we can also supply with double and triple braids for higher pressures. If mechanical protection is required then we can add an external spiral which keeps the braid off the ground if being used for loading/unloading for example.

Movements

Loops, laterals

MOVEMENTS

LOOPS, LATERALS

Hose does not move in the same way as an expansion joint; there must be no axial movement and all movements should be the result of angulation. Apply a portion of the hose perpendicular to the expected movement and support it so that the minimum bend radius is always maintained. Sharp bends should be accomplished using elbows. FlexEJ will help you specify the hose, understanding the nature of the movement and suggesting a suitable solution.

Projects

Hose assembly solutions

PROJECTS

HOSE ASSEMBLY SOLUTIONS

FlexEJ specialises in engineering and manufacturing metal hose assemblies to order. Full documentation packages, NDT, material traceability and testing are all part of what we offer. Complex materials, jacketed hoses, very high pressures… – please get in touch and we will be pleased to help.

Metal Hose End Fitting Types

There is a great variety of possible end fittings and connections, typically the two end fittings are dissimilar; we can accommodate any requirement as long as the material and fitting are weldable. The most common fitting styles are:

| Weld end | Flanged – fixed |

| Flanged – loose, stub + swivel | Lever Lock Coupling – male |

| Lever Lock Coupling – female | Threaded – male |

| Threaded – female, fixed | Threaded – female, swivel nut flat seat |

| Threaded – female, swivel nut cone seat | Quick Release |

Metal Hose Materials

The end fitting material does not need to be the same as the hose – carbon steel fittings with stainless steel hose is a common choice. You may specify any weldable material for the end fitting or a screwed fitting welded to the hose and any threaded fitting coupled to it.

Metal hose is stocked in the following materials:

| Stainless Steel 304/L | Stainless Steel 321 |

| Stainless Steel 316/L | High Nickel Alloy 625 |

| Monel 400 | Hastelloy C276 |

Other grades are available to order. Hose braid is typically 304 stainless steel or 316 with higher alloy core.

Temperature Deration

When considering the hose material it is important to also consider the design temperature.

The allowable pressure rating of metal hose for a particular material will decrease with temperature being typically around 0.5 of rated pressure at 500C – the exact figure depending on the material.

Metal Hose Design & Application

The actual service conditions the hose will experience – such as pulsating or discontinuous demand, type and frequency of motion, working temperature – must be taken into account at the design stage.

Metal hose bending radius

The allowable bending radius for the hose depends on the type of motion the hose will experience, this is described as:- Single motion – infrequent or installation-only movement.

- Repeated motion – low frequency / motion without major dynamic demand.

- Dynamic motion – higher frequency / continuous motion with dynamic demand.

Metal Hose Movement

Metal hose must not be installed to accommodate axial movement or torsion. Movement ideally should be lateral, in a single plane, with the hose or piping incorporating elbows to achieve this as required. Please refer to our hose installation guidelines in the Technical Downloads section.

Metal Hose Projects

If required we can offer the same extensive NDT and manufacturing documentation as with our metal expansion joints and pressure vessels. This capability allows us to serve demanding end users in the petrochemical, refining and energy markets with unique custom designed metal hose assemblies.

Traceability

Material traceability and NDT are managed through a specially developed data base which integrates with our business system. The database allows for instant reporting of material and inspection status together with indexing / retrieval of certification for the manufacturing data book.

Can't see what you want? Need help?

Call us. Or use Live Chat.

For instant advice. We can custom-design and engineer almost any expansion joint you need for delivery in the UK or worldwide. Call our expert team on +44 (0) 1384 881188 Or email us sales@flexej.co.uk

Frequently Asked Questions

A. Yes, a strip wound hose can be used as a liner within a convoluted metal hose assembly. Flexibility is reduced to some extent. For technical assistance contact us or use our Live Chat facility.

A. The bend radius depends on the hose diameter and the type of motion. The static bend radius is the minimum radius the hose can bend to for a few movement cycles without fatigue failure. The dynamic bend radius is the minimum radius the hose can bend to for many movement cycles without fatigue failure. ISO10380 defines these parameters. For technical assistance please contact us or use our Live Chat facility.

A. Metal hose is manufactured in continuous lengths from metal strip which is welded and then formed. We offer U form convoluted metal hose which is mechanically or hydraulically formed, with standard or close pitch. Typically the hose conforms to ISO ISO10380. For technical assistance please contact us or use our Live Chat facility.

A. No, we only manufacture to order but lead times can be very short. For sales assistance please contact us or use our Live Chat facility.

A. Our Flange Finder contains details for many common flanges. Typically, to be able to make the identification you need to know the bore size or outside diameter and number of bolts. For technical assistance contact us or use our Live Chat facility.